Importance of Backhoe-Loader Safety & Maintenance Programs

Comprehensive Safety

- Integrated safety and maintenance programs verify critical systems daily while ensuring scheduled service maintains safe operating condition over time. This dual approach protects operators from immediate hazards while preventing long-term deterioration of brakes, hydraulics, ROPS, and attachments.

Regulatory Compliance

- OSHA mandates daily equipment inspections before operation, while manufacturers require scheduled preventive maintenance for warranty compliance. Comprehensive programs satisfy both requirements, provide audit-ready documentation, and demonstrate organizational commitment to safety and equipment care.

Equipment Reliability

- Combining daily safety checks with preventive maintenance creates layered protection against failures - operators catch immediate issues while technicians address developing problems during scheduled service, preventing unexpected breakdowns and maximizing equipment availability.

Cost Optimization

- Integrated safety and maintenance programs minimize total ownership costs by catching problems early through daily inspections, preventing expensive failures through scheduled maintenance, reducing emergency repair costs, and extending equipment service life through proper care.

Sign up to track backhoe-loader safety and maintenance digitally

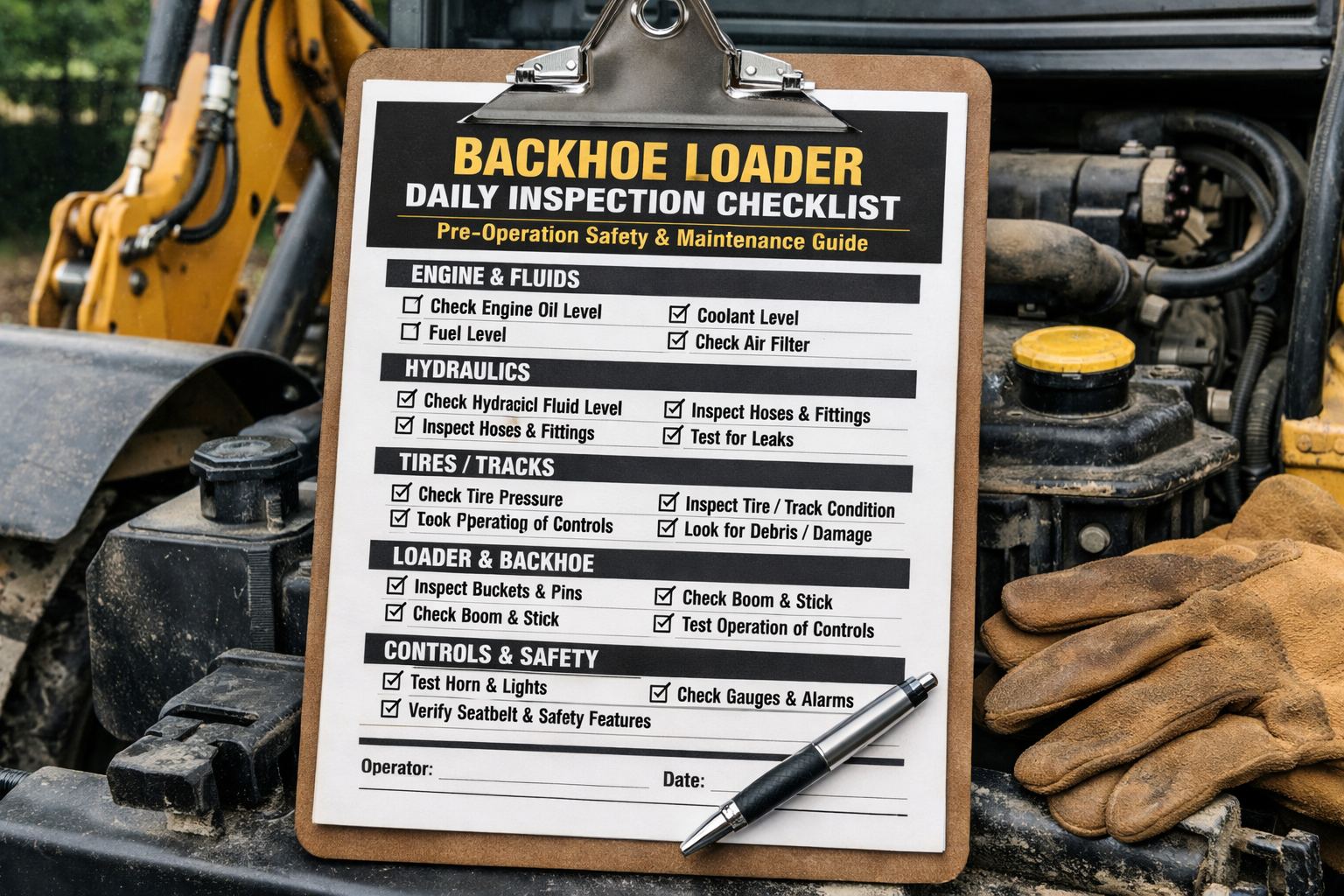

1. ENGINE COMPARTMENT

Critical engine and fluid system verification combining daily level checks with scheduled service intervals - operators verify proper levels daily while technicians perform fluid changes, filter replacements, and system inspections during preventive maintenance. Comprehensive engine compartment care prevents failures and ensures reliable operation. Schedule a 30-minute demo to see how digital platforms integrate daily safety checks with scheduled maintenance, track both operator inspections and technician service completion, and maintain complete equipment history for compliance and warranty protection.

2. FROM THE GROUND

Comprehensive walk-around inspection covering attachments, hydraulic systems, and structural components:

3. INSIDE THE CAB

Operator safety systems and control verification:

Why Use Digital Fleet Management for Backhoe-Loader Safety & Maintenance?

HVI App Benefits for Integrated Safety & Maintenance Programs:

- ✓ Combined platform managing both daily safety inspections and scheduled maintenance

- ✓ Mobile checklists for operator daily inspections with immediate defect reporting

- ✓ Automated preventive maintenance scheduling based on operating hours

- ✓ Complete audit trail documenting both safety compliance and service completion

- ✓ Photo documentation capabilities for defects and repair verification

- ✓ Integrated reporting showing safety inspection trends and maintenance costs

Book a demo to see integrated safety and maintenance tracking

Frequently Asked Questions About Backhoe-Loader Safety & Maintenance

1. What's the difference between safety inspections and maintenance on backhoe-loaders?

Safety inspections are operator-conducted pre-shift checks verifying equipment is safe to operate that shift—checking fluid levels, testing brakes, verifying safety devices function. Preventive maintenance consists of scheduled service tasks performed by technicians at specific intervals—changing fluids, replacing filters, adjusting components, and comprehensive system inspections. Both are essential: inspections ensure immediate safety, maintenance prevents long-term deterioration.

2. How do safety and maintenance programs work together?

Integrated programs create layered protection—operators perform daily safety checks identifying immediate issues before operation, while scheduled maintenance addresses developing problems and performs service before failures occur. Daily inspections often identify items requiring maintenance attention, while proper maintenance reduces defects found during daily inspections. Together they maximize equipment safety and reliability.

3. Who is responsible for safety inspections versus preventive maintenance?

Equipment operators are responsible for daily pre-shift safety inspections before operating backhoe-loaders. Qualified maintenance technicians perform scheduled preventive maintenance requiring specialized tools, technical knowledge, and manufacturer training. Supervisors oversee both programs ensuring inspections occur, defects are addressed, and maintenance schedules are followed. Clear responsibility assignment prevents gaps in equipment care.

4. What documentation is required for backhoe-loader safety and maintenance compliance?

OSHA requires documented daily pre-operation safety inspections showing equipment was verified safe before use. Manufacturer warranties require documented preventive maintenance proving service intervals were followed. Complete documentation includes dated inspection records with operator signatures, service completion records with technician verification, defect reports with corrective actions, and parts receipts. Digital systems maintain permanent, searchable records satisfying all requirements.

5. How does digital management improve safety and maintenance programs?

Digital platforms integrate daily safety inspections and scheduled maintenance in one system, ensuring operators complete inspections before equipment operation, automatically scheduling preventive maintenance based on operating hours, tracking defects from identification through repair completion, maintaining complete equipment history for audits and warranty claims, and generating comprehensive reports showing safety compliance and maintenance costs. Sign up for a free trial and get instant access to integrated backhoe-loader safety and maintenance management, mobile inspection capabilities, automated scheduling, and complete compliance documentation - no credit card required for your 14-day trial period.

6. What are the consequences of inadequate safety inspections or deferred maintenance?

Skipped safety inspections allow unsafe equipment operation risking operator injuries, OSHA citations, and liability exposure. Deferred maintenance causes accelerated wear, catastrophic failures, expensive emergency repairs, warranty voidance, and equipment damage from operating with deteriorated components. Both create unnecessary costs, regulatory violations, and safety risks. Systematic programs prevent these consequences through consistent inspection and maintenance.

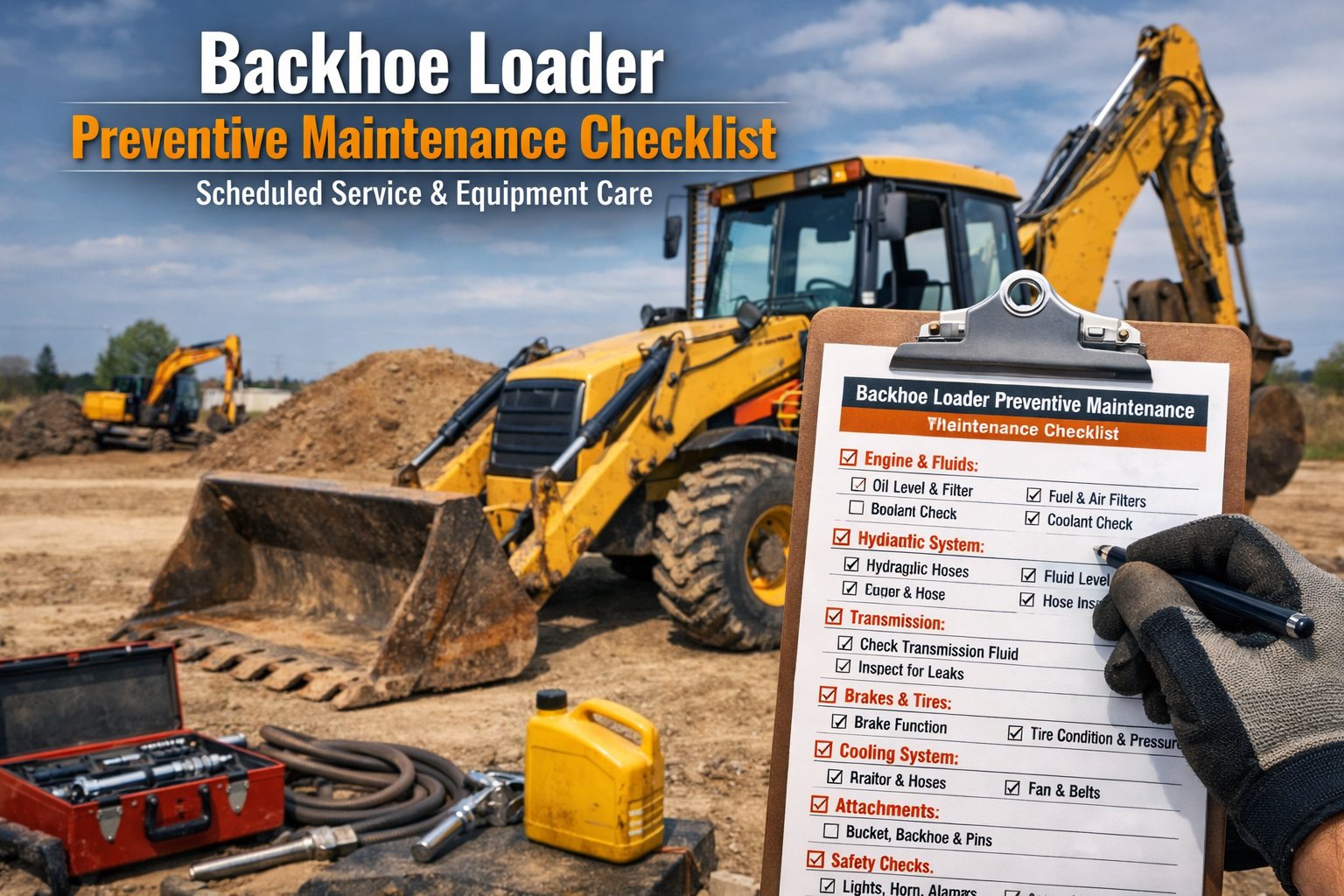

Take Action: Implement Comprehensive Safety & Maintenance Programs

Download our FREE Backhoe-Loader Safety and Maintenance Checklist and establish integrated programs combining daily safety verification with systematic preventive maintenance. Digital fleet management ensures daily inspections occur before operation, automates maintenance scheduling, maintains complete compliance documentation, and protects your workforce and equipment investment. Build a culture of safety and equipment care.

Protect Operators and Equipment with Integrated Safety & Maintenance Programs

Complete coverage: daily safety inspections verify immediate operating condition while scheduled preventive maintenance ensures long-term reliability—all managed through unified digital platform.