Importance of Backhoe Loader Preventive Maintenance

Equipment Longevity

- Systematic preventive maintenance based on manufacturer-recommended service intervals extends backhoe loader service life significantly, prevents premature component wear, protects expensive hydraulic and drivetrain systems, and maintains equipment value for eventual resale or trade-in. Start your free 14-day trial to track preventive maintenance with automated hour-based service schedules, maintenance history documentation, parts tracking, and service completion verification that maximizes equipment life.

Uptime Maximization

- Proactive preventive maintenance catches wear before failure, eliminates unexpected breakdowns during critical construction phases, ensures equipment remains operational throughout demanding schedules, and prevents costly mid-job repairs that halt entire crews.

Cost Management

- Scheduled maintenance is significantly less expensive than emergency repairs, prevents catastrophic component failures from operating with low fluids or worn parts, optimizes parts replacement timing, and reduces total ownership costs through proper equipment care.

Safety Assurance

- Regular preventive maintenance ensures safety-critical systems including brakes, hydraulics, ROPS, seat belts, and attachments remain in proper working condition, protecting operators from equipment failures and maintaining compliance with safety regulations.

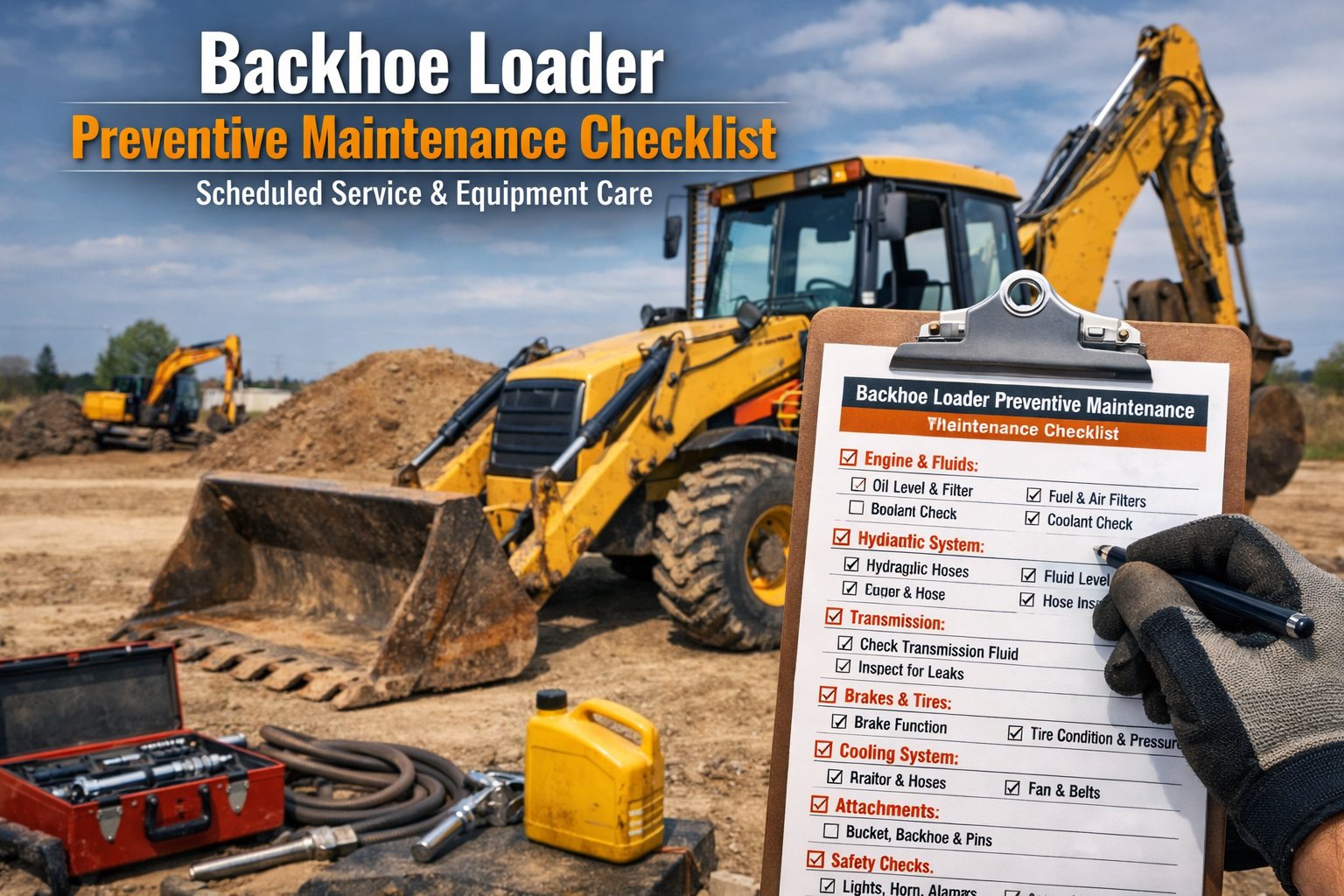

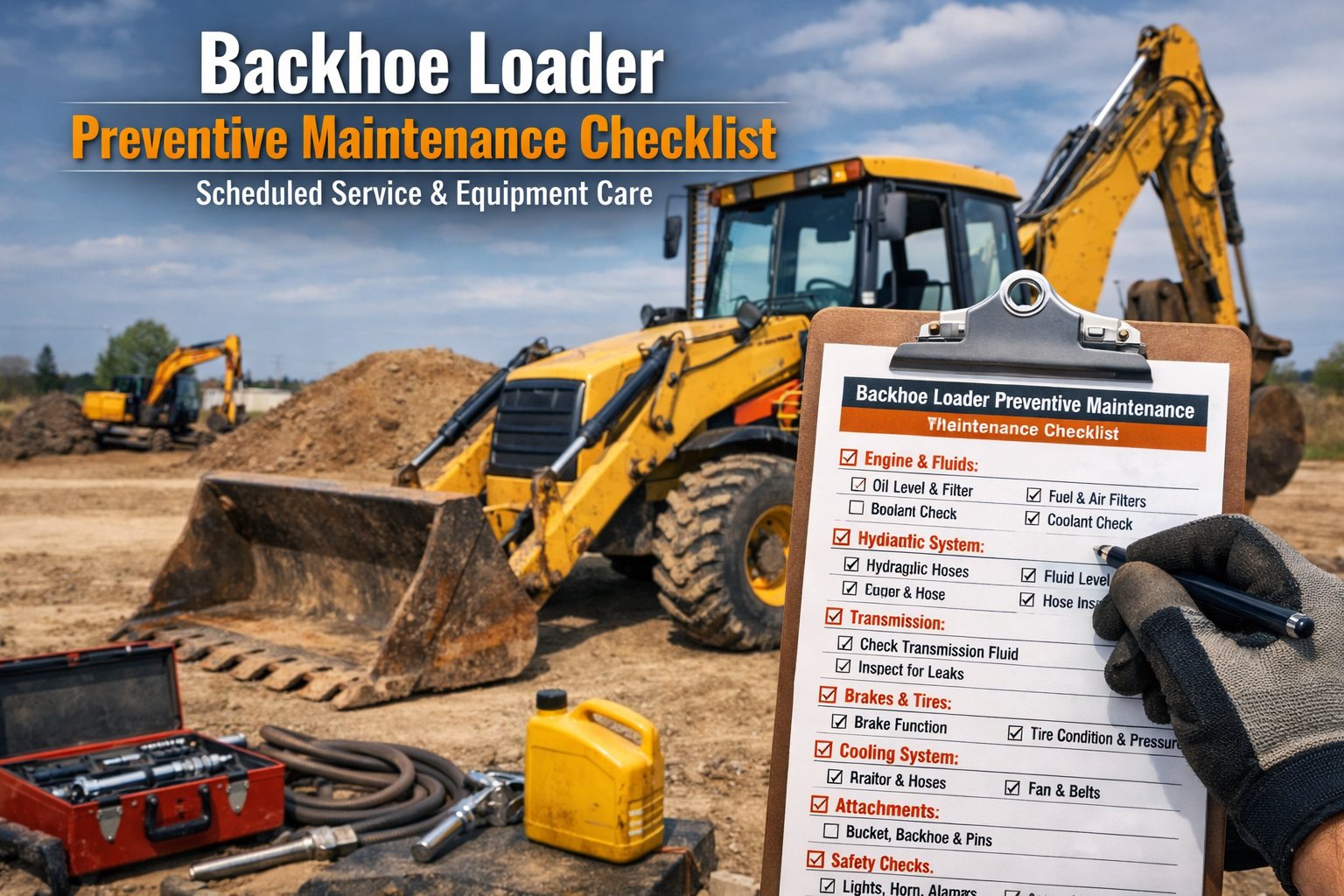

1. ENGINE COMPARTMENT

Critical engine and fluid system maintenance - scheduled servicing of engine oil, transmission, brakes, cooling system, and filters prevents expensive failures and maintains reliable operation. Proper fluid levels and component condition are essential for equipment longevity. Schedule a 30-minute demo to see how digital maintenance platforms automate hour-based service scheduling, track fluid changes, manage filter replacements, and alert maintenance teams when service intervals approach.

2. FROM THE GROUND

Comprehensive undercarriage, attachment, and system inspection during scheduled maintenance intervals:

3. INSIDE THE CAB

Operator environment and safety system maintenance verification:

Why Use Digital Fleet Management for Backhoe Loader Preventive Maintenance?

HVI App Benefits for Heavy Equipment Maintenance Programs:

- ✓ Automated service scheduling based on operating hours and calendar intervals

- ✓ Maintenance history tracking for every machine in your fleet

- ✓ Parts inventory management and procurement tracking

- ✓ Service completion verification with technician sign-off

- ✓ Cost tracking per machine and per service type

- ✓ Maintenance alerts preventing overdue service intervals

Book a demo to see automated preventive maintenance tracking

Frequently Asked Questions About Backhoe Loader Preventive Maintenance

1. What are typical preventive maintenance intervals for backhoe loaders?

Backhoe loaders typically require preventive maintenance at manufacturer-specified intervals based on operating hours: minor service every 50-100 hours, intermediate service every 250-500 hours, and major service every 500-1000 hours. Specific intervals vary by manufacturer and model. Additional annual maintenance is required regardless of hours for items like coolant system service and comprehensive inspections.

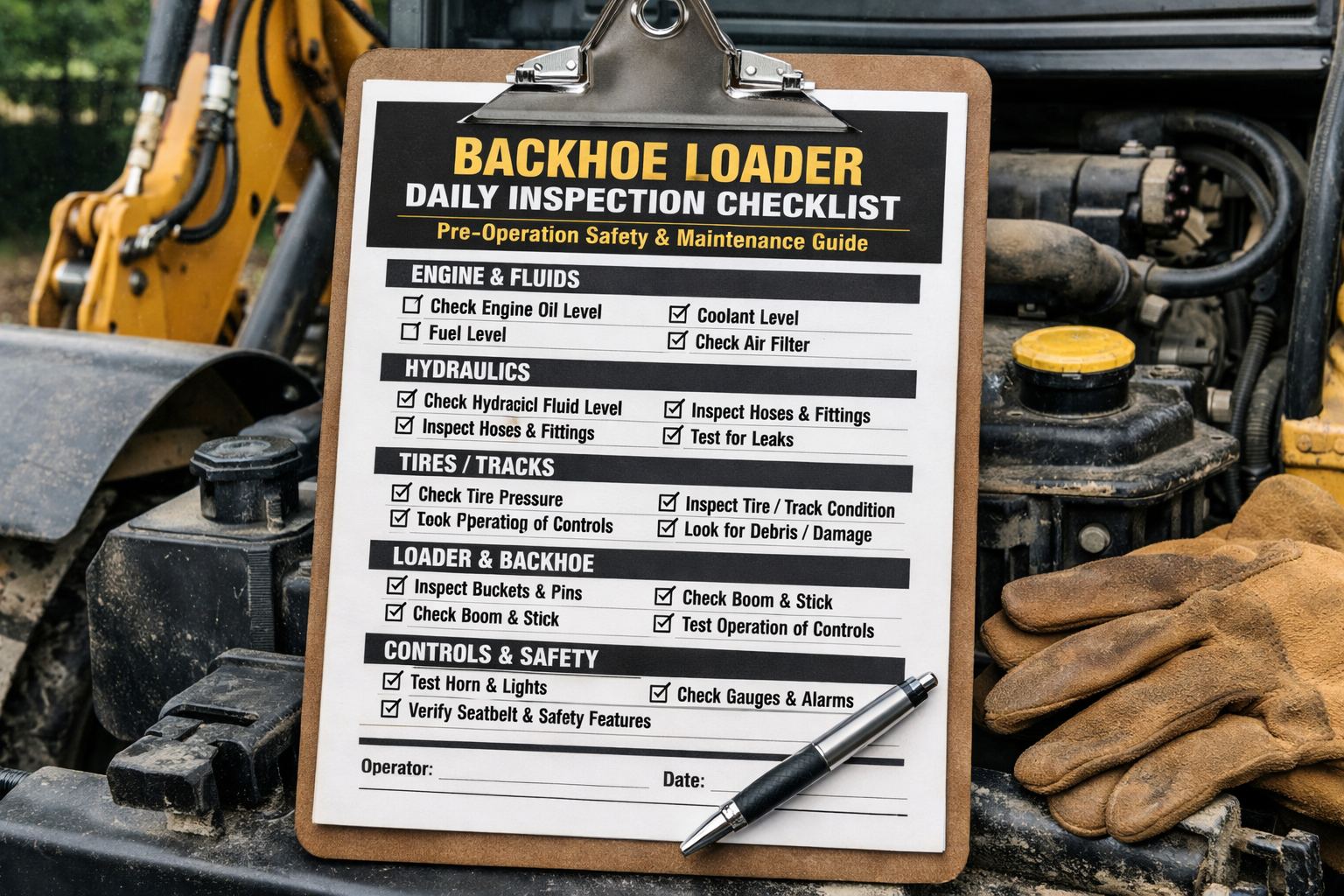

2. What's the difference between daily inspections and preventive maintenance?

Daily inspections are operator-conducted pre-shift checks verifying equipment is safe to operate and identifying immediate issues. Preventive maintenance consists of scheduled service tasks performed by qualified technicians at specific hour or time intervals, including fluid changes, filter replacements, component adjustments, and comprehensive system inspections that require technical expertise and specialized tools.

3. What are the most critical preventive maintenance items for backhoe loaders?

Critical maintenance items include engine oil and filter changes, hydraulic system fluid and filter service, transmission fluid service, brake system inspection and adjustment, cooling system maintenance, air filter replacement, fuel filter changes, greasing all pivot points and cylinders, hydraulic hose inspection, and bucket/attachment wear component inspection. Neglecting these items leads to expensive failures.

4. Can operators perform preventive maintenance or does it require technicians?

Basic preventive maintenance tasks like checking fluid levels, greasing fittings, and cleaning filters can be performed by trained operators. However, most preventive maintenance including fluid changes, system adjustments, component replacements, and comprehensive inspections require qualified technicians with proper training, tools, and expertise to ensure work is performed correctly and safely.

5. How does digital maintenance tracking improve preventive maintenance programs?

Digital maintenance tracking automates service scheduling based on actual operating hours, sends alerts before service intervals are due, maintains complete maintenance history for warranty compliance and resale value, tracks parts costs and labor hours per machine, prevents missed service intervals that void warranties, and generates reports showing fleet maintenance status and costs. Sign up for a free trial and get instant access to customizable backhoe loader maintenance schedules, hour-based service tracking, and complete equipment maintenance records - no credit card required for your 14-day trial period.

6. What happens if preventive maintenance is skipped or delayed?

Skipping or delaying preventive maintenance causes accelerated component wear, increased likelihood of catastrophic failures, higher repair costs from operating with contaminated fluids or worn parts, reduced equipment life, potential warranty voidance, increased downtime from unexpected breakdowns, and safety risks from deteriorated brakes, hydraulics, or structural components. Deferred maintenance is always more expensive than scheduled maintenance.

Take Action: Implement Comprehensive Backhoe Loader Preventive Maintenance

Download our FREE Backhoe Loader Preventive Maintenance Checklist and establish systematic maintenance programs that extend equipment life and prevent costly breakdowns. Digital fleet management automates hour-based service scheduling, tracks maintenance completion, manages parts inventory, maintains warranty compliance records, and prevents expensive failures. Protect your equipment investment and maximize uptime.

Extend Equipment Life with Systematic Preventive Maintenance

Complete coverage: engine servicing, hydraulic system maintenance, transmission service, attachment inspection, cooling system care—all scheduled and tracked automatically with digital maintenance management.