Importance of Backhoe Loader Daily Inspections

Operator Safety

- Daily pre-operation inspections verify critical safety systems including ROPS integrity, seat belt functionality, backup alarms, hydraulic system integrity, and attachment security, preventing accidents and protecting operators from equipment failures during excavation and loading operations.

Equipment Reliability

- Systematic daily inspections catch fluid leaks, worn components, and developing issues before they cause breakdowns, ensuring backhoe loaders remain operational throughout shifts and preventing costly mid-day failures that halt entire crews.

Regulatory Compliance

- OSHA and manufacturer requirements mandate daily equipment inspections before operation. Documented daily inspection records demonstrate compliance, protect your organization during audits, and provide defensible safety documentation.

Cost Prevention

- Daily inspections identify minor issues before they become expensive repairs, prevent damage from operating equipment with low fluids or failing components, and extend backhoe loader service life through early problem detection.

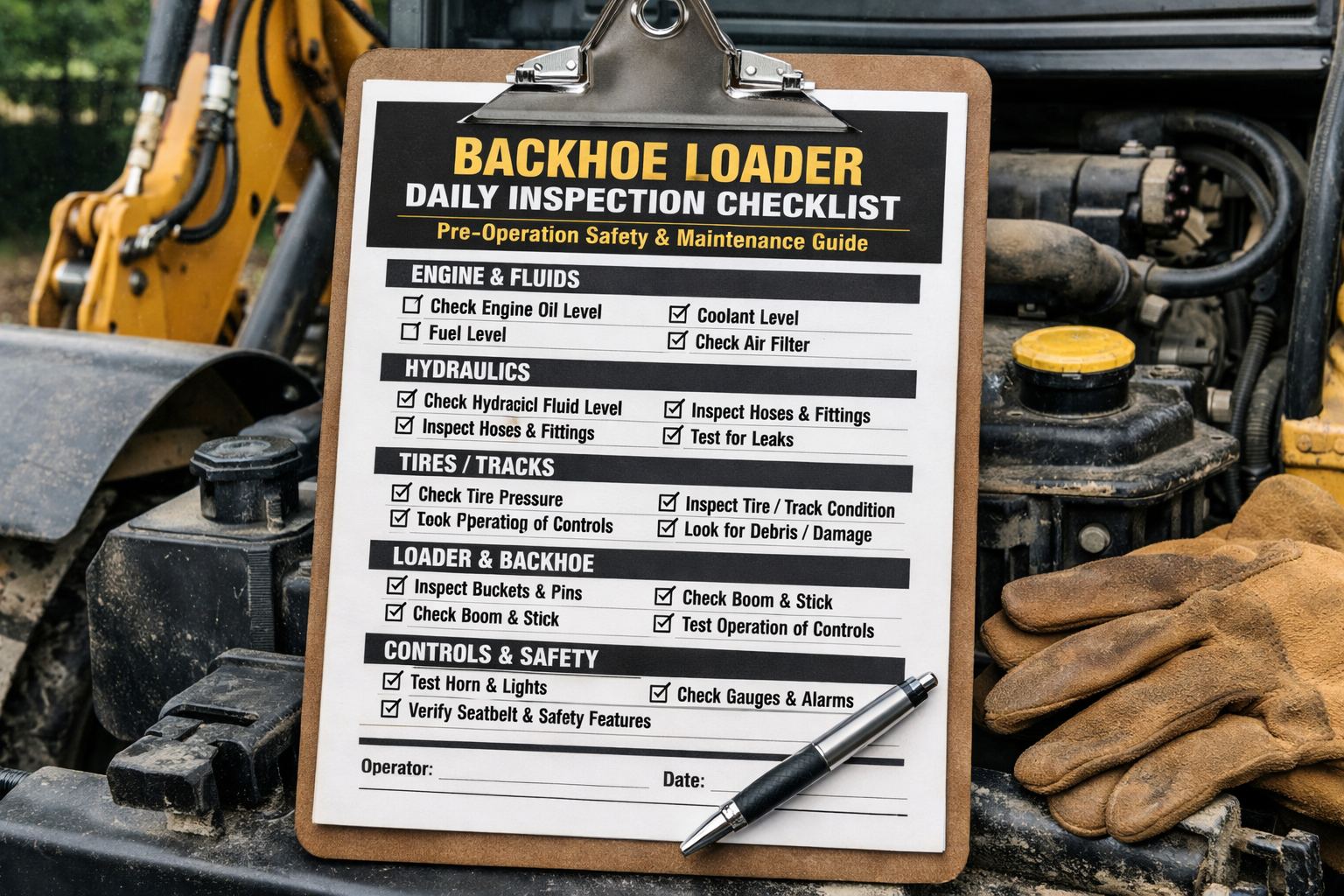

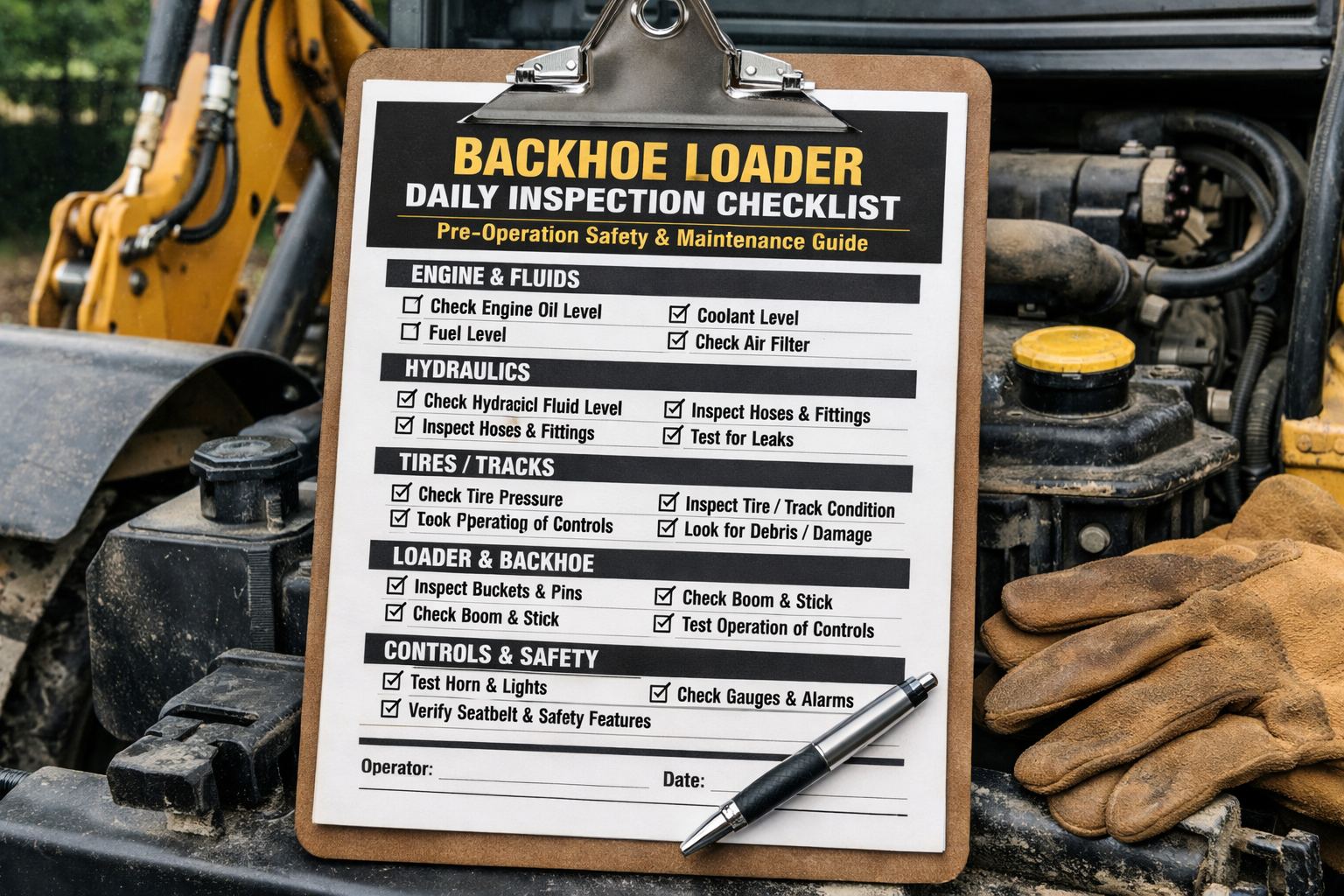

1. ENGINE COMPARTMENT

Critical engine and fluid system inspection - proper fluid levels and component condition are essential for reliable backhoe loader operation. Low engine oil, coolant, or hydraulic fluid can cause catastrophic equipment damage. Schedule a 30-minute demo to see how digital inspection platforms streamline daily checks with mobile checklists, automatic defect alerts to maintenance teams, photo documentation capabilities, and instant supervisor notification of critical issues.

2. FROM THE GROUND

Comprehensive walk-around inspection covering all external components, attachments, and safety systems:

3. INSIDE THE CAB

Operator environment and control system verification:

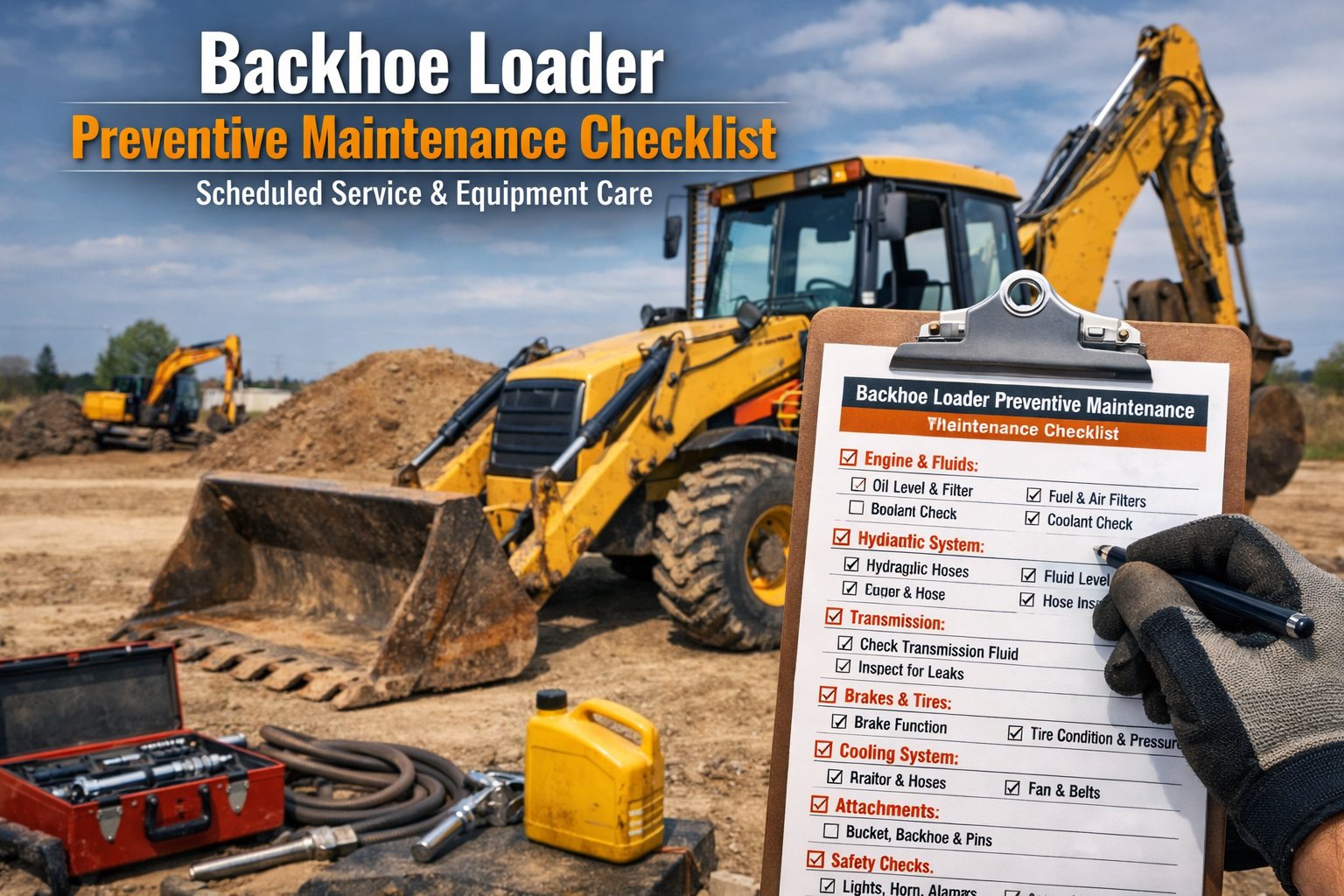

Why Use Digital Fleet Management for Daily Backhoe Loader Inspections?

HVI App Benefits for Heavy Equipment Daily Inspections:

- ✓ Mobile inspection checklists accessible from job sites before equipment operation

- ✓ Photo documentation of defects, leaks, and component wear

- ✓ Immediate supervisor and maintenance alerts for critical safety issues

- ✓ Digital records proving compliance with OSHA and manufacturer requirements

- ✓ Automatic equipment lockout preventing operation until defects are resolved

- ✓ Complete inspection history tracking trends and recurring issues

Frequently Asked Questions About Backhoe Loader Daily Inspections

1. Are daily inspections required for backhoe loaders?

Yes, OSHA regulations and equipment manufacturer guidelines require daily pre-operation inspections of heavy equipment including backhoe loaders. Operators must verify critical safety systems, fluid levels, hydraulic integrity, and overall machine condition before beginning work each shift. Documented inspections demonstrate regulatory compliance and due diligence.

2. Who is responsible for conducting daily backhoe loader inspections?

Equipment operators are typically responsible for completing daily pre-shift inspections before operating backhoe loaders. Operators must be trained on inspection procedures, understand critical safety items, know how to identify defects, and understand protocols for reporting issues. Supervisors oversee inspection compliance and ensure defects are resolved before equipment operation.

3. What should operators do if they identify a defect during daily inspection?

Operators must immediately report any safety-critical defects to supervisors, tag equipment as out-of-service if defects affect safe operation, document defects in inspection records, and not operate equipment until qualified technicians complete repairs and verify equipment is safe to operate. Critical defects include hydraulic leaks, brake issues, seat belt damage, ROPS damage, or attachment security problems.

4. How long should daily backhoe loader inspections take?

Thorough daily inspections typically require 10-15 minutes to complete properly, checking all engine fluids, walking completely around the machine inspecting attachments and hydraulic systems, and verifying all cab controls and safety devices. While this seems time-consuming, systematic inspections prevent hours of downtime from equipment failures and demonstrate safety commitment.

5. How does digital inspection software improve backhoe loader safety programs?

Digital inspection software ensures operators complete inspections before equipment operation through mobile prompts, provides photo documentation of defect conditions for maintenance teams, creates timestamped records proving inspections occurred, automatically alerts supervisors to critical safety issues, prevents equipment operation when defects are identified, and generates comprehensive safety reports for compliance audits. Sign up for a free trial and get instant access to customizable backhoe loader inspection checklists, mobile capabilities for field operators, and automated defect tracking - no credit card required for your 14-day trial period.

6. What are the most commonly missed items during backhoe loader daily inspections?

Commonly overlooked items include hydraulic oil level and leaks underneath the machine, GET (ground engaging tools) retainer condition on buckets, stabilizer cylinder integrity, seat belt mounting damage, ROPS structural condition, backup alarm functionality, and DEF tank levels on newer equipment. Digital checklists ensure operators systematically check every item rather than relying on memory.

Take Action: Implement Systematic Backhoe Loader Daily Inspections

Download our FREE Backhoe Loader Daily Inspection Checklist and establish consistent pre-operation safety programs that protect operators and prevent equipment failures. Digital fleet management ensures inspections are completed before equipment operation, provides immediate defect reporting, maintains compliance documentation, and creates a culture of safety across construction operations. Protect your workforce and your equipment investment.

Protect Operators with Consistent Daily Pre-Operation Inspections

Complete coverage: engine fluids, hydraulic systems, loader and backhoe attachments, tires, controls, ROPS, safety devices—all verified before equipment operation with digital inspection tracking.