Importance of OSHA Asbestos Compliance Inspections

Worker Health Protection

- OSHA asbestos compliance inspections protect workers from deadly diseases including asbestosis, lung cancer, and mesothelioma. Systematic verification of exposure controls, air monitoring, and respiratory protection prevents life-threatening health consequences from asbestos fiber inhalation. Start your free 14-day trial to implement digital asbestos compliance programs with automated inspection scheduling, exposure monitoring tracking, training documentation, and real-time regulatory compliance reporting.

Regulatory Compliance

- Documented asbestos inspections demonstrate compliance with 29 CFR 1910.1001, satisfy OSHA audit requirements, prevent citations and penalties, and protect your organization from enforcement actions and legal liability.

Exposure Prevention

- Systematic inspections verify engineering controls function properly, regulated areas are maintained, air monitoring occurs on schedule, and all exposure reduction measures meet OSHA's permissible exposure limits.

Documentation Requirements

- Comprehensive inspection records satisfy OSHA's extensive documentation requirements for exposure assessments, air monitoring results, training records, medical surveillance, and compliance program effectiveness, creating defensible records for regulatory audits.

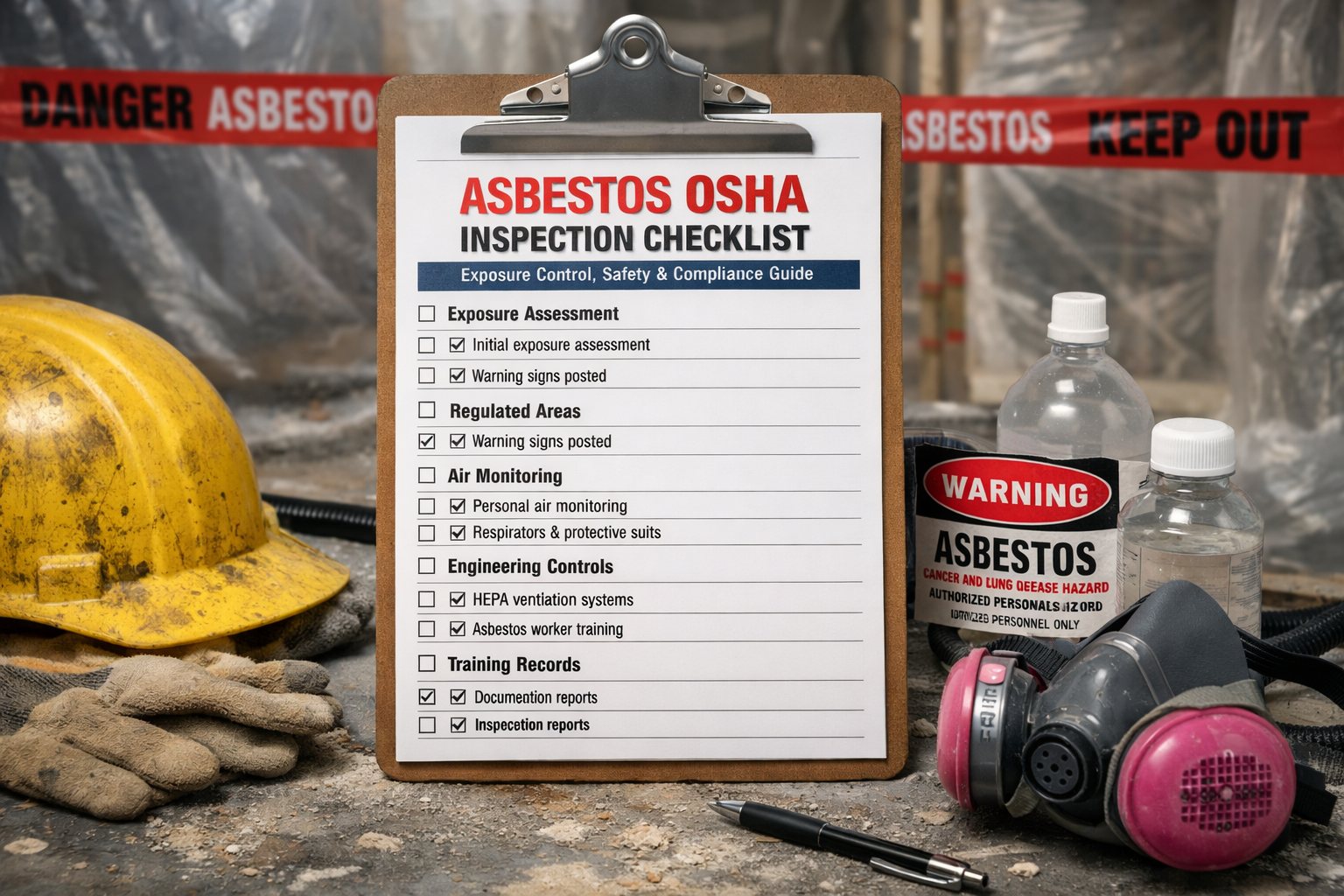

Asbestos OSHA Inspection

Comprehensive OSHA compliance verification covering exposure limits, engineering controls, regulated areas, PPE, training, and documentation requirements - asbestos compliance failures result in serious OSHA citations, worker health risks, and significant legal liability. Regular systematic inspections ensure all regulatory requirements are met and maintained. Schedule a 30-minute demo to see how digital compliance management automates asbestos inspection schedules, tracks air monitoring results, maintains training records, manages regulated area documentation, and generates audit-ready compliance reports.

Why Use Digital Compliance Management for Asbestos Safety?

HVI App Benefits for OSHA Asbestos Compliance:

- ✓ Automated inspection scheduling for regulated areas and air monitoring

- ✓ Digital documentation of exposure assessments and compliance measures

- ✓ Training record management with automatic refresher reminders

- ✓ Photo documentation of engineering controls and regulated areas

- ✓ Medical surveillance tracking and respirator fit test scheduling

- ✓ Audit-ready compliance reports for OSHA inspections

Frequently Asked Questions About OSHA Asbestos Compliance

1. What are OSHA's permissible exposure limits for asbestos?

OSHA's asbestos standard establishes a permissible exposure limit (PEL) of 0.1 fibers per cubic centimeter (f/cc) as an 8-hour time-weighted average (TWA), and an excursion limit (EL) of 1.0 f/cc averaged over 30 minutes. Employers must implement engineering controls, work practices, and respiratory protection to maintain exposures below these limits.

2. When must regulated areas be established?

Regulated areas must be established wherever airborne concentrations of asbestos exceed or can reasonably be expected to exceed the TWA or EL. These areas must be demarcated, access must be limited to authorized personnel, and warning signs must be posted. Eating, drinking, smoking, and applying cosmetics are prohibited in regulated areas.

3. What air monitoring is required for asbestos compliance?

Initial exposure monitoring is required for all employees who may be exposed to airborne asbestos at or above the action level (0.1 f/cc TWA). If exposures exceed the TWA or EL, periodic monitoring must be conducted at least every six months. Additional monitoring is required when process changes, work practices, or control measures could affect exposures.

4. What training is required for asbestos workers?

All employees exposed to asbestos at or above the action level must receive comprehensive training at the time of initial assignment and at least annually thereafter. Training must cover health effects, work practices, engineering controls, respiratory protection, emergency procedures, medical surveillance, and the contents of the OSHA asbestos standard.

5. How does digital compliance software help with asbestos safety?

Digital compliance software automates critical asbestos safety requirements including inspection scheduling, air monitoring tracking, training record management with automatic refresher alerts, medical surveillance coordination, exposure assessment documentation, and audit-ready compliance reporting that satisfies OSHA documentation requirements. Sign up for a free trial and get instant access to customizable OSHA asbestos compliance checklists, automated monitoring schedules, and comprehensive training documentation - no credit card required for your 14-day trial period.

6. What records must be maintained for asbestos compliance?

Employers must maintain exposure monitoring records for 30 years, medical surveillance records for the duration of employment plus 30 years, training records for one year, and written compliance programs. All records must be made available to employees, former employees, OSHA, and NIOSH upon request. Proper recordkeeping is essential for demonstrating compliance during OSHA inspections.

Take Action: Maintain OSHA Asbestos Compliance

Download our FREE Asbestos OSHA Inspection Checklist and establish systematic compliance programs that protect worker health and satisfy all regulatory requirements. Digital compliance management automates inspection scheduling, maintains comprehensive documentation, tracks exposure monitoring, manages training records, and generates audit-ready reports for OSHA inspections. Protect your workers from asbestos-related diseases and your organization from regulatory violations.

Protect Workers with Comprehensive Asbestos Compliance Programs

Complete OSHA coverage: exposure limits, regulated areas, air monitoring, engineering controls, respiratory protection, training, medical surveillance, and documentation—all tracked automatically with digital compliance management.