Importance of Articulated Hauler Maintenance

Equipment Uptime

- Systematic preventive maintenance maximizes articulated hauler availability during critical project phases, prevents unexpected breakdowns that halt production, and ensures consistent material movement capacity throughout demanding work cycles. Start your free 14-day trial to track maintenance schedules automatically with digital service reminders, maintenance history tracking, and real-time equipment status monitoring that keeps your haulers operational.

Operator Safety

- Regular inspection of brakes, steering systems, ROPS, seat belts, and hydraulic components protects operators from equipment failures, prevents accidents, and ensures all safety systems function properly under demanding hauling conditions.

Cost Control

- Proactive maintenance catches wear before component failure, prevents catastrophic damage to expensive drivetrain and hydraulic systems, reduces emergency repair costs, and extends articulated hauler service life significantly.

Performance Optimization

- Proper maintenance ensures hydraulic systems operate efficiently, engines deliver full power, articulation joints move smoothly, and all systems work together to maintain optimal hauling capacity and fuel efficiency throughout the equipment's operational life.

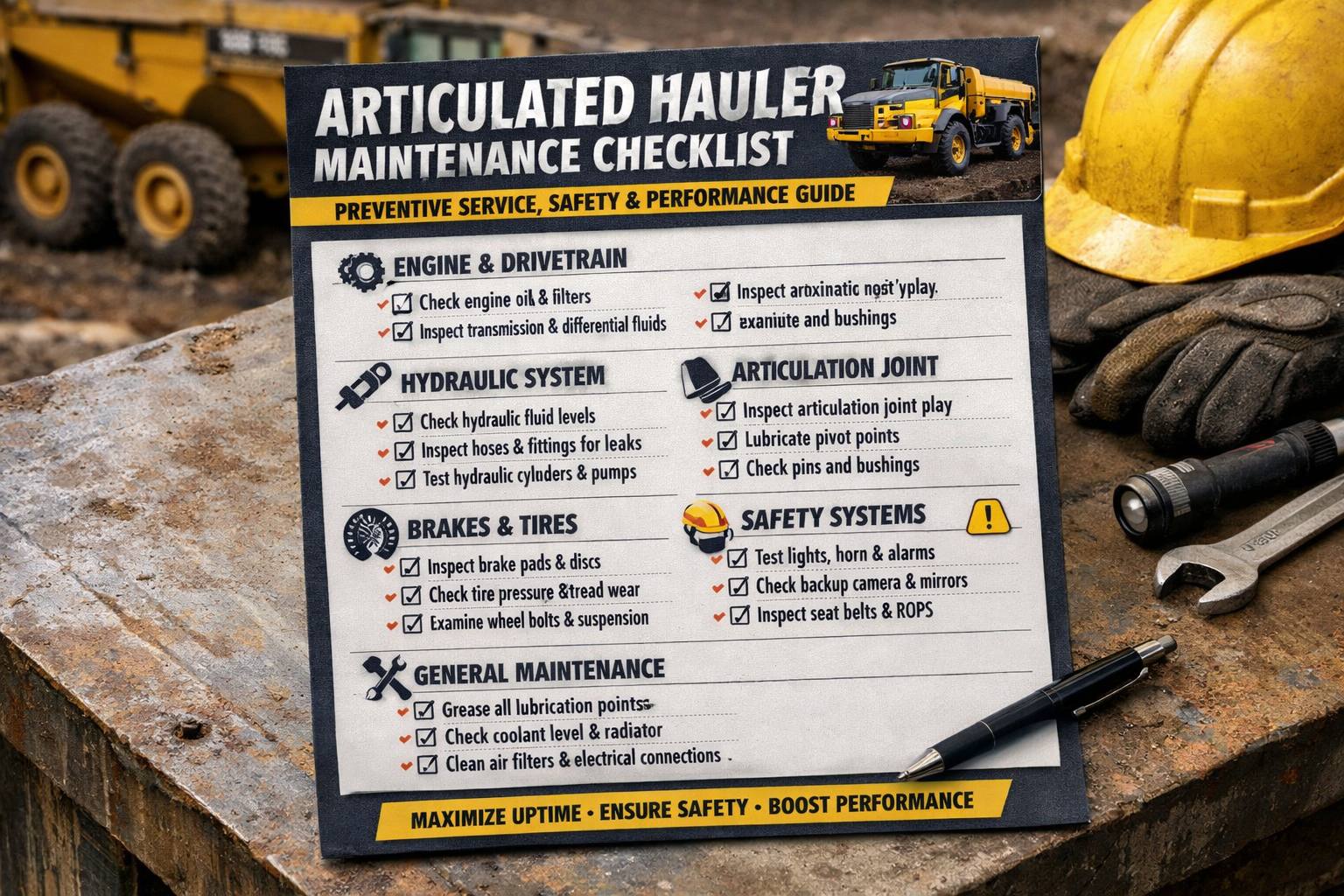

1. ENGINE / STEERING COMPARTMENT

Critical engine and steering system components - proper fluid levels, filter condition, and system integrity are essential for reliable hauler operation. Regular inspection of hydraulic steering components prevents loss of control and ensures safe maneuverability with heavy loads. Schedule a 30-minute demo to see how digital maintenance tracking automates service intervals, tracks fluid changes, monitors filter replacements, and provides maintenance alerts based on operating hours and equipment condition.

2. FROM THE GROUND

Comprehensive undercarriage and structural inspection covering all critical load-bearing and safety components:

3. INSIDE THE CAB

Operator environment and safety system verification:

4. ON THE MACHINE, OUTSIDE CAB

External safety features and operator access points:

Why Use Digital Fleet Management for Articulated Hauler Maintenance?

HVI App Benefits for Heavy Equipment Maintenance:

- ✓ Track maintenance based on operating hours and service intervals

- ✓ Automated service reminders for filters, fluids, and inspections

- ✓ Digital checklists accessible from mobile devices on job sites

- ✓ Photo documentation of wear, leaks, and component condition

- ✓ Complete maintenance history for each articulated hauler

- ✓ Parts inventory management and procurement tracking

Frequently Asked Questions About Articulated Hauler Maintenance

1. How often should articulated haulers be inspected?

Articulated haulers require daily pre-shift inspections covering basic safety items, fluids, tires, and lights. Comprehensive maintenance inspections should follow manufacturer intervals based on operating hours—typically every 250, 500, and 1000 hours. Severe operating conditions may require more frequent service intervals.

2. What are the most critical maintenance items for articulated haulers?

Critical maintenance items include hydraulic system integrity (steering, hoist, brakes), articulation joint condition and lubrication, brake system functionality, tire pressure and tread depth, engine oil and filters, transmission fluid, cooling system, and all safety systems including ROPS, seat belts, and backup alarms.

3. Why is articulation joint maintenance so important?

The articulation joint allows the hauler to navigate rough terrain while maintaining stability. Worn or damaged articulation components cause poor steering response, uneven tire wear, structural stress, and potential loss of control. Regular inspection, lubrication, and bearing maintenance are essential for safe operation and equipment longevity.

4. How does operating environment affect maintenance schedules?

Harsh environments with dust, mud, extreme temperatures, or abrasive materials accelerate wear on filters, seals, bearings, and hydraulic components. Operators in mining, quarry, or severe conditions should increase maintenance frequency, perform more frequent filter changes, and conduct additional inspections to prevent premature component failure.

5. How does digital maintenance tracking benefit heavy equipment fleets?

Digital maintenance tracking automates service scheduling based on operating hours, provides mobile access to inspection checklists on job sites, creates permanent maintenance records for each machine, tracks parts usage and costs, alerts managers to overdue services, and generates comprehensive equipment history reports. Sign up for a free trial and get instant access to customizable articulated hauler maintenance checklists, hour-based service scheduling, and complete equipment tracking - no credit card required for your 14-day trial period.

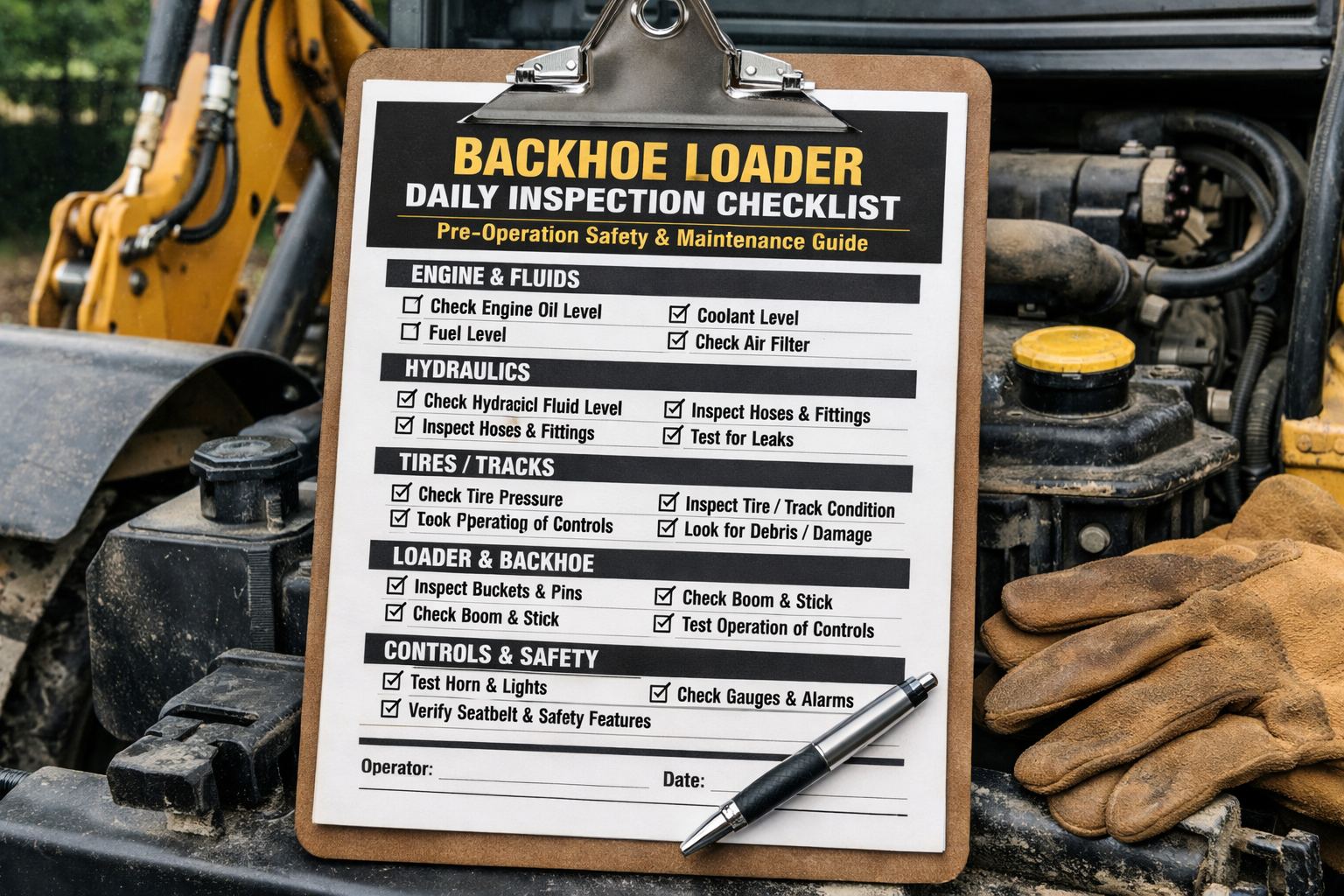

6. What should be included in daily pre-shift inspections?

Daily pre-shift inspections should verify fluid levels (engine oil, hydraulic, coolant), tire condition and pressure, lights and backup alarms, brake functionality, steering response, seat belt operation, ROPS integrity, hydraulic leaks, unusual noises or vibrations, and overall machine condition. Operators should document any defects before starting work.

Take Action: Implement Systematic Articulated Hauler Maintenance

Download our FREE Articulated Hauler Maintenance Checklist and establish proactive maintenance programs that maximize equipment uptime. Digital fleet management automates service scheduling based on operating hours, provides mobile inspection access for operators and technicians, maintains complete maintenance history for resale value, and prevents costly breakdowns during critical project phases. Keep your articulated haulers productive, safe, and profitable.

Maximize Uptime with Proactive Articulated Hauler Maintenance

Complete coverage: engine, hydraulics, articulation joints, brakes, suspension, dump body, safety systems, and operator environment—all tracked automatically with digital maintenance management.