Importance of Daily Pre-Check Maintenance

Early Issue Identification

- Daily pre-checks help identify potential equipment issues before they cause breakdowns, ensuring problems are caught early and addressed promptly.

Equipment Readiness

- Systematic pre-start inspections ensure equipment is ready for safe operation, verifying fluid levels, safety devices, and overall condition before work begins.

Reduced Downtime

- Regular pre-check maintenance minimizes unexpected downtime by preventing failures during operation and keeping equipment in optimal working condition.

Safe Compliant Operations

- Daily maintenance checklists support safe, compliant operations by ensuring all safety items are inspected and documentation is complete before equipment use.

1. Documentation

Documentation inspection points:

2. Other Safety Items

Other safety items inspection points:

3. Physical

Physical inspection points:

4. Signs and Equipemt

Signs and equipment inspection points:

Why Use Digital Fleet Management?

HVI App Benefits for Daily Maintenance:

- ✓ Automate daily pre-check schedules and compliance tracking

- ✓ Digital inspection forms for operators

- ✓ Instant issue reporting with photo documentation

- ✓ Real-time equipment status and maintenance alerts

- ✓ Create audit-ready records for compliance

- ✓ Ensure every pre-check is completed before operation

Frequently Asked Questions About Daily Maintenance Pre-Check

1. Why is daily pre-check maintenance important?

Daily pre-checks help identify issues early, ensure equipment readiness, reduce downtime, and support safe, compliant operations. They catch potential problems before they cause equipment failures or safety incidents.

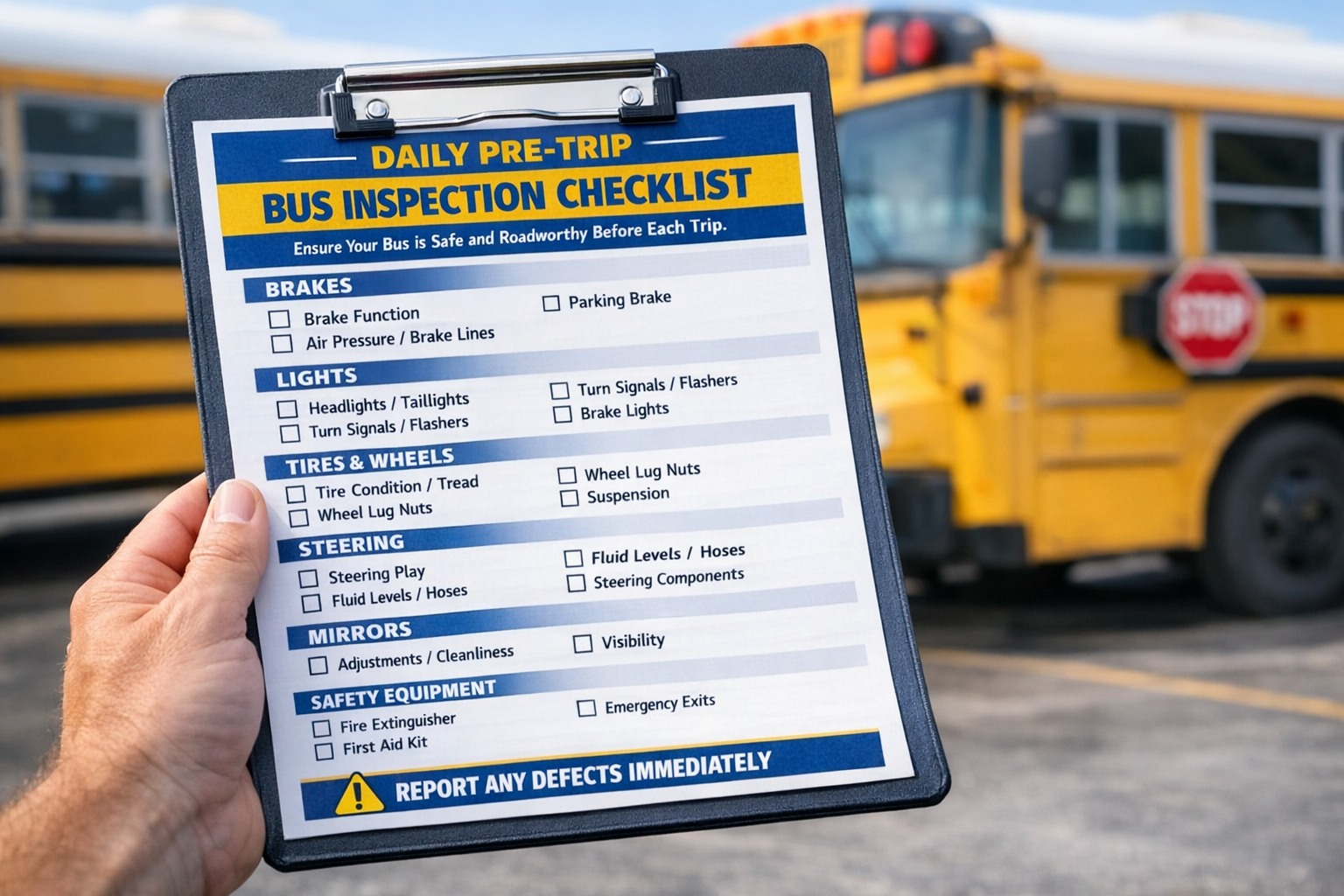

2. What should be inspected during a daily pre-check?

A daily pre-check should cover documentation, safety items (fire extinguisher, spill kit, first aid kit), physical condition (engine, fluids, lights, tires), and signs/equipment (safety harness, emergency stops, radios, hazard cones).

3. How long does a daily pre-check take?

A thorough daily pre-check typically takes 10-20 minutes depending on the equipment type and condition. This small time investment prevents costly breakdowns and ensures safe operation throughout the workday.

4. How does the HVI App help manage daily pre-checks?

The HVI App provides digital pre-check forms, automates inspection schedules, enables instant issue reporting with photos, and creates audit-ready records. Operators can complete inspections on mobile devices before starting work.

5. What happens if I skip daily pre-check maintenance?

Skipping daily pre-checks can lead to equipment failures, safety incidents, unplanned downtime, and compliance issues. Regular pre-checks are essential for maintaining safe, reliable equipment operations.

6. Who should perform daily pre-check maintenance?

Daily pre-checks should be performed by trained operators before each shift or equipment use. Operators must document any issues found and report them to maintenance personnel before operating the equipment.

Take Action: Implement Daily Pre-Check Maintenance

Download our FREE Daily Maintenance Checklist (Pre-Check) and start implementing thorough equipment inspections. Integrating digital fleet management with your maintenance process streamlines compliance—ensuring your equipment is ready, safe, and properly documented before each use. Experience the power of automated maintenance tracking to improve reliability and reduce downtime.

Keep Your Equipment Ready Every Day

Follow a proven pre-check process: documentation, safety items, physical condition, and equipment—all tracked automatically with digital fleet management.