A standardized fleet vehicle inspection checklist is the difference between catching a $50 brake pad issue and paying $15,000 for an emergency roadside repair—plus the fines, downtime, and CSA score damage that follow. Yet only 7% of motor carriers pass DOT audits without a single violation. The other 93% face penalties that could have been prevented with consistent, thorough inspections. This guide provides everything fleet managers need to build inspection processes that actually work: the complete checklist items organized by vehicle system, DOT compliance requirements, the most common mistakes that lead to violations, and why digital checklists outperform paper in every measurable way. Whether you're standardizing inspections for a 10-vehicle fleet or a 500-vehicle operation, this is your roadmap to compliance, safety, and reduced maintenance costs. Start your free trial or book a demo to standardize your fleet inspections.

Why Fleet Vehicle Inspections Matter

Fleet inspections aren't just regulatory checkboxes—they're the foundation of safe operations, controlled maintenance costs, and audit readiness. Understanding why inspections matter helps build the organizational commitment needed to do them consistently and thoroughly.

Prevent Accidents & Save Lives

The FMCSA estimates that Driver Vehicle Inspection Reports (DVIRs) help prevent approximately 14,000 accidents annually through early defect identification. A brake failure, tire blowout, or steering malfunction caught during inspection is a breakdown prevented—and potentially a life saved.

Reduce Maintenance Costs

Emergency roadside repairs cost 4x more than planned maintenance. Inspections catch small problems—a worn belt, low fluid, minor leak—before they cascade into catastrophic failures. Fleets with consistent inspection programs report 25-40% lower repair costs.

Maintain DOT Compliance

Operating an out-of-service vehicle carries fines up to $19,277 per violation. Missing or incomplete inspection records are immediate red flags during audits. Consistent DVIRs demonstrate the systematic safety management that regulators—and insurers—require.

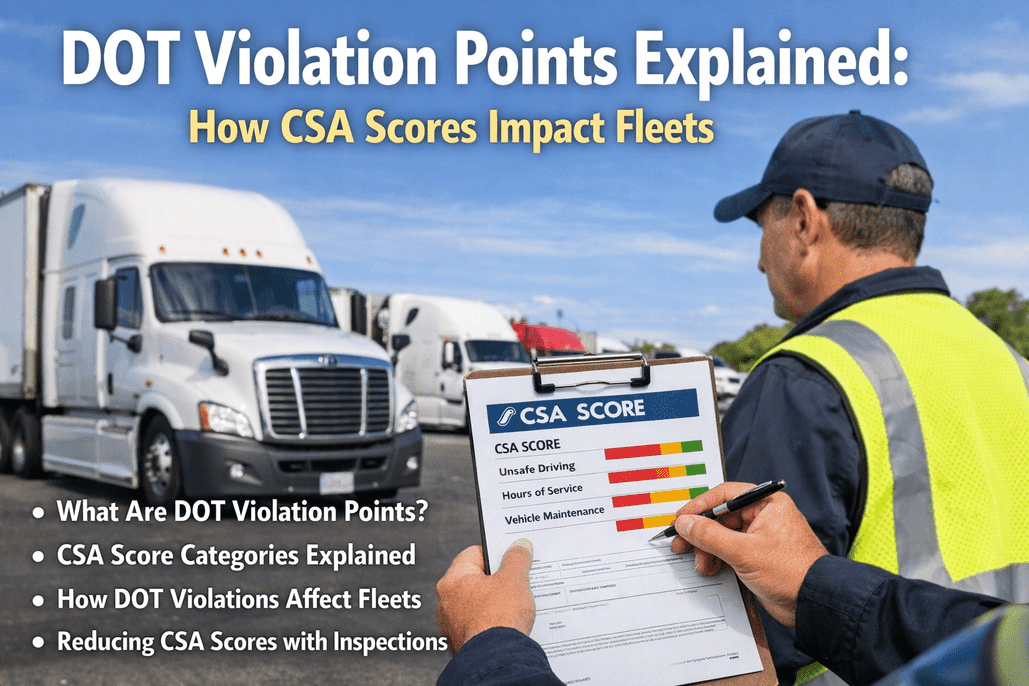

Protect CSA Scores & Insurance Rates

Vehicle maintenance violations directly impact your CSA Safety Measurement System scores. Poor scores mean higher insurance premiums, lost shipper relationships, and increased audit scrutiny. Good inspection records are your best defense.

Complete Fleet Vehicle Inspection Checklist

A thorough inspection covers every system that affects vehicle safety and operation. This checklist is organized by vehicle area to match how drivers actually walk around and inspect vehicles—making it easier to follow consistently without missing critical items.

Exterior Walk-Around

- Tire pressure matches manufacturer specifications

- Tread depth adequate (minimum 4/32" steer, 2/32" drive/trailer)

- No cuts, bulges, cracks, or exposed cords

- No uneven wear patterns indicating alignment issues

- Lug nuts tight, no missing or damaged studs

- Rims free of cracks, bends, or rust

- Wheel seals not leaking

- Spare tire present, properly inflated, accessible

- Headlights operational (low and high beam)

- Taillights and brake lights functional

- Turn signals working (front, rear, side)

- Hazard/emergency flashers operational

- Clearance and marker lamps working

- License plate light functional

- All reflectors intact and visible

- No cracked or fogged lens covers

- No visible body damage affecting safety

- Doors open, close, and latch properly

- Mirrors secure, properly adjusted, no cracks

- Windshield free of major cracks (no crack >11" in wiper area)

- Fuel cap secure, no leaks

- Frame free of cracks or severe rust at attachment points

- Mud flaps/splash guards present and secure

Under Hood / Engine Compartment

- Engine oil level and condition (check dipstick)

- Coolant level adequate (check reservoir)

- Brake fluid at proper level

- Power steering fluid level

- Transmission fluid level and condition

- Windshield washer fluid filled

- No visible leaks under vehicle or in engine bay

- Belts free of cracks, fraying, or glazing

- Proper belt tension (no excessive slack)

- Hoses firm but flexible (not too soft or stiff)

- No bulges, cracks, or leaks in hoses

- Battery terminals clean, free of corrosion

- Battery connections secure

- Wiring properly routed, no exposed wires

Brake System

- Brake pedal firm, not spongy

- Adequate brake pedal reserve (doesn't go to floor)

- No pulling to one side when braking

- Brake pads/shoes have adequate thickness

- Rotors/drums free of scoring or cracks

- Brake lines free of leaks, cracks, or damage

- No unusual noises when braking

- Air pressure builds to operating range

- Low air pressure warning activates properly

- Air compressor operating correctly

- Air lines free of damage or leaks

- Glad hands properly connected (if trailer)

- Air tanks drained of moisture

- Parking brake holds vehicle securely

Steering & Suspension

- Steering wheel free play within limits (max 30° for CMVs)

- No tight spots or binding during rotation

- Power steering fluid at proper level

- No power steering leaks

- Steering column secure, no excessive play

- Tie rod ends secure, no excessive wear

- Drag link and pitman arm secure

- Springs not broken, sagging, or shifted

- U-bolts and hangers secure

- Shock absorbers not leaking or damaged

- No clunking noises when turning

- Vehicle sits level (no leaning)

- Air bags inflated properly (if equipped)

Cab Interior & Safety Equipment

- All dashboard warning lights illuminate on startup

- No warning lights remain on after startup

- Speedometer and odometer functioning

- Oil pressure, temperature, voltage gauges working

- Horn operational

- Windshield wipers and washers working

- Heater, defroster, and A/C functional

- Seatbelts retract, latch, and release properly

- No fraying or damage to seatbelt webbing

- Fire extinguisher present, charged, accessible

- Three reflective triangles present

- Spare electrical fuses available

- First aid kit present (if required)

- Required documentation available (registration, insurance)

Coupling & Trailer (if applicable)

- Fifth wheel properly greased

- Locking jaws closed around kingpin

- Release handle in locked position

- No visible cracks in fifth wheel

- Mounting bolts secure

- Kingpin not damaged or worn

- Air and electrical connections secure

- Trailer lights functioning

- Trailer brakes engaging properly

- Landing gear raised and secured

- Doors secure, seals intact

- Cargo properly secured (if loaded)

Want this checklist built into a digital inspection app your drivers can complete in minutes? Start your free trial with pre-built DOT-compliant templates, or schedule a demo to see how digital checklists work.

DOT Compliance Requirements

Understanding exactly what the DOT requires—and when—helps you build inspection processes that satisfy regulators while actually improving safety. Here are the key compliance requirements every fleet must meet:

Pre-Trip Inspection

§392.7, §392.8, §396.13When: Before operating the vehicle each day

What: Driver must be satisfied the vehicle is in safe operating condition. Must check: service brakes, parking brake, steering, lights, tires, horn, wipers, mirrors, coupling devices, wheels and rims, and emergency equipment.

Documentation: Not required to be documented by federal regulation, but many carriers require written pre-trips for liability protection.

Key Point: If previous DVIR noted deficiencies, driver must review and sign acknowledgment that repairs were made before operating.

En-Route Inspection

§392.9, §397.17When: During operation, at specified intervals

Cargo Securement: Check within first 50 miles after loading, then every 3 hours, 150 miles, or at duty change—whichever comes first.

Hazmat Tires: Check before trip, any time vehicle is parked, and at end of trip.

Key Point: Quick walk-around inspection every time vehicle is parked helps catch developing issues before they become breakdowns.

Post-Trip Inspection (DVIR)

§396.11When: At end of each day's work

Property Carriers: Required only when defects or deficiencies are discovered (unless carrier policy requires daily).

Passenger Carriers: Required at end of every workday, regardless of whether defects found.

Documentation: Written DVIR with driver signature. Carrier must certify repairs made before vehicle operates again.

Retention: DVIRs must be retained for at least 3 months.

Annual Inspection

§396.17When: Every 12 months (rolling calendar)

Who: Must be performed by qualified inspector

Applies To: Interstate CMVs with GVWR >10,001 lbs, intrastate CMVs >26,001 lbs, hazmat vehicles, passenger vehicles with 16+ passengers.

Documentation: Inspection reports must be retained for 14 months from inspection date. Proof of inspection must be displayed on vehicle or carried by driver.

FMCSA has clarified that electronic DVIRs (eDVIRs) are explicitly allowed under regulations. Electronic DVIRs must contain all required information, include digital signatures, route to required recipients, be stored for 3 months minimum, and be producible for DOT audits. Many fleet management systems now integrate eDVIRs with ELD platforms for streamlined compliance.

Record Retention Requirements

| Document Type | Retention Period | Notes |

|---|---|---|

| DVIRs | 3 months minimum | Most carriers retain longer for liability protection |

| Annual Inspection Reports | 14 months | From date of inspection |

| Maintenance Records | 1 year + 6 months | While vehicle in carrier's control, plus 6 months after |

| ELD/HOS Records | 6 months | Must be transferable via web service or local transfer |

Need help meeting DOT compliance requirements? Book a free consultation to learn how our digital inspection system ensures every DVIR meets regulatory requirements, or start your free trial today.

Common Inspection Mistakes That Lead to Violations

The same inspection failures appear again and again during DOT audits and roadside inspections. Understanding these common mistakes—and how to prevent them—is essential for building a violation-free inspection program.

Drivers sign inspection forms without actually performing the inspection—usually due to time pressure or complacency.

Missing signatures, illegible handwriting, incomplete fields, or forms that can't be located during audits.

Brake system violations are among the most common DOT citations—and the most dangerous to overlook.

Lighting violations are among the most frequent roadside inspection failures—often because bulbs burn out between inspections.

Lack of proof of annual inspection is one of the most frequent DOT audit failures—even when the inspection was actually performed.

Defects are reported but repairs aren't completed, documented, or acknowledged by drivers before the next trip.

Most Common DOT Inspection Violations

Why Digital Checklists Outperform Paper

Paper inspection forms have been the industry standard for decades—but they introduce errors, create compliance gaps, and waste time that digital solutions eliminate entirely. Here's why fleets are making the switch:

- Illegible handwriting causes confusion

- Forms get lost, damaged, or misfiled

- Easy to skip fields or entire sections

- No photo documentation capability

- Manual data entry creates delays

- Difficult to search for specific records

- No real-time visibility for managers

- Audit preparation takes hours

- Clear, standardized data entry

- Cloud storage—records never lost

- Required fields prevent incomplete forms

- Photo capture documents defects

- Instant data sync—no manual entry

- Searchable database in seconds

- Real-time dashboard visibility

- Audit-ready reports in one click

Digital workflows with guided steps and tap-to-select options reduce inspection time from 30-45 minutes to 5-8 minutes.

Automated report generation eliminates manual data entry. Compliance admin drops from 12 hours/week to 1 hour.

Required fields, validation rules, and digital signatures eliminate the incomplete and illegible forms that cause audit failures.

Every inspection timestamped with GPS location, photos, and digital signatures. Complete history retrievable instantly.

Key Digital Checklist Capabilities

Step-by-step inspection flow ensures nothing is missed. Visual cues show exactly what to check and photograph.

Complete inspections without internet. Data syncs automatically when connection returns—no inspections lost.

Capture images of defects with timestamps and GPS. Visual proof protects against disputes and strengthens audits.

Defects trigger automatic work orders routed to maintenance. No defect falls through the cracks.

Automated reminders for annual inspections, expiring certifications, and overdue maintenance items.

Create checklists specific to vehicle types, routes, or regulatory requirements. One system for all inspection needs.

Ready to replace paper forms with digital checklists that actually improve compliance? Start your free trial with DOT-compliant templates ready to use immediately, or book a demo to see the full platform in action.

Frequently Asked Questions

Standardize Your Fleet Inspections Today

A consistent, thorough inspection program is your first line of defense against breakdowns, accidents, and DOT violations. HVI's digital inspection platform gives your drivers the tools to complete compliant inspections in minutes—with photo documentation, automatic work orders, and audit-ready records.

No credit card required • DOT-compliant templates included • Setup in under 10 minutes