Your excavator idles 6 hours daily burning 9 gallons doing nothing. Your haul trucks waste 15% of fuel on inefficient routes. Preventable maintenance issues cost 8-12% fuel efficiency. Heavy equipment fleets waste 20-25% of fuel through idle time, poor maintenance, and operator habits. These aren't unavoidable costs—they're solvable with monitoring, maintenance, and operator accountability. Start tracking fuel usage and eliminate waste, or schedule a fuel reduction assessment to identify your biggest opportunities.

23%

Average Fuel Waste In Heavy Equipment Fleets

$14K

Annual Waste Per Equipment Unit

15-22%

Fuel Cost Reduction Achievable In 90 Days

40%

Of Waste Is From Excessive Idle Time

Stop Wasting Fuel In Your Heavy Equipment Fleet

Track idle time, optimize maintenance, and implement operator controls with Fleet Rabbit's equipment monitoring system.

Start Reducing Costs

Get Assessment

Why Heavy Equipment Wastes More Fuel

- High idle time - Equipment left running during breaks, waiting, loading

- Deferred maintenance - Clogged filters, wrong oil, poor tire pressure reduce efficiency 10-15%

- Operator inefficiency - Aggressive operation, poor technique waste fuel

- No monitoring - Can't identify which units or operators waste fuel

Result: 20-25% fuel waste, unknown accountability

- Idle reduction - Auto-shutoff policies, operator training reduce idle 50-60%

- Proactive maintenance - PM schedules maintain peak efficiency, prevent degradation

- Operator accountability - Performance tracking drives behavior improvement

- Real-time monitoring - Telematics shows exactly where fuel goes

Result: 15-22% cost reduction, full accountability

5 Proven Strategies To Reduce Fuel Costs

Strategy #1

Aggressive Idle Time Reduction

Heavy equipment burns 0.5-1.5 gallons per hour idling. Implement 5-minute auto-shutoff policy (except when prohibited). Track idle hours daily per unit. Alert operators exceeding limits. Most effective single strategy—reduces fuel costs 8-12% alone.

Impact:

50-60% idle reduction = 8-12% total fuel savings

Strategy #2

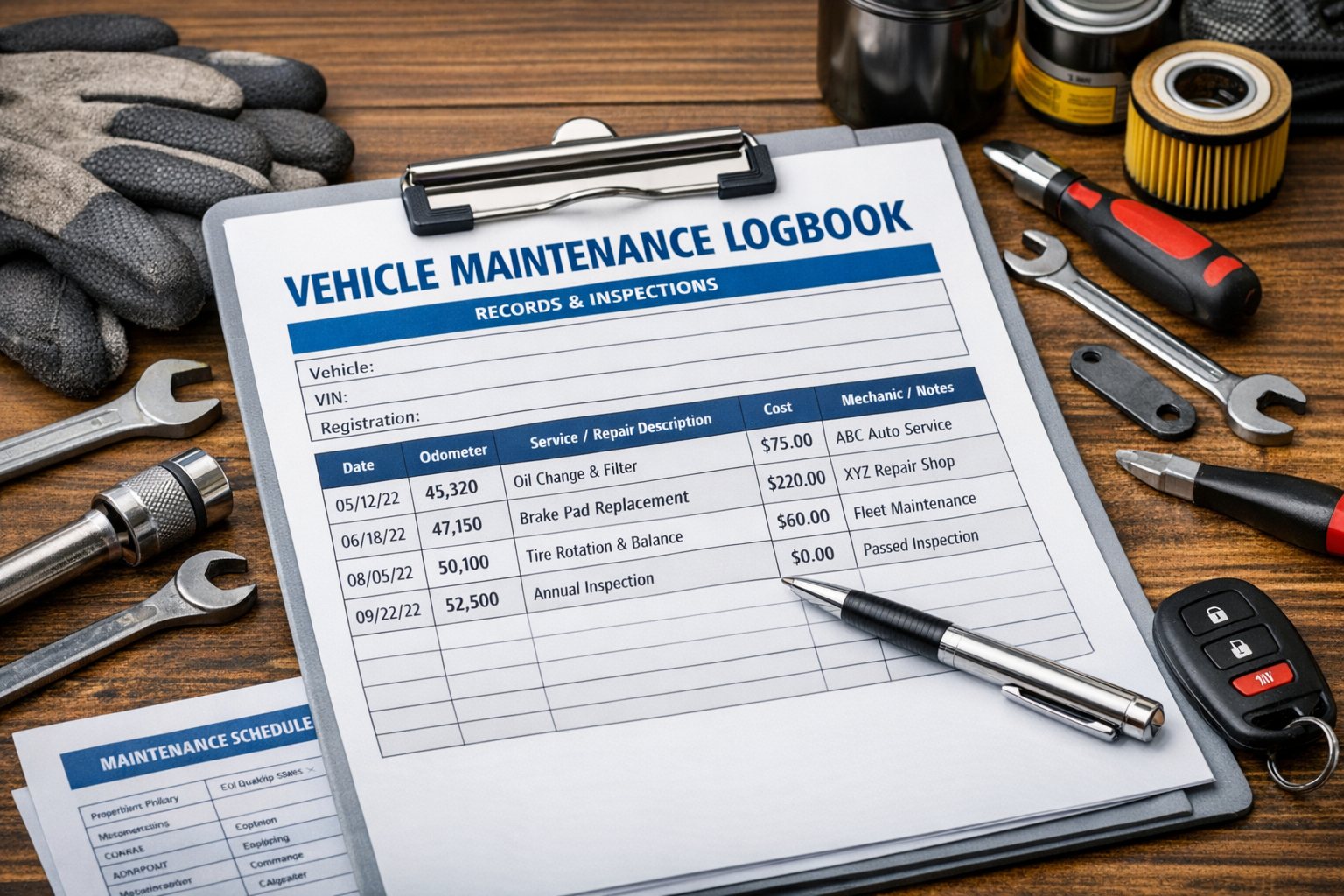

Preventive Maintenance Optimization

Dirty air filters reduce efficiency 10%. Wrong oil viscosity costs 3-5%. Low tire pressure adds 5-8%. Implement hour-based PM schedules, not "when it breaks." Track fuel economy per unit—5%+ degradation triggers inspection. Need automated maintenance tracking? Sign up for Fleet Rabbit's PM reminder system with fuel efficiency monitoring.

Efficiency Gain:

8-12% fuel savings from proper maintenance

Strategy #3

Operator Training & Accountability

Aggressive operation (rapid acceleration, high RPM, harsh braking) wastes 10-15% fuel. Train operators on efficient technique: smooth acceleration, proper gear selection, minimize idle. Publish weekly fuel efficiency scorecards. Coach bottom 20% operators monthly.

Improvement:

10-15% efficiency gain from operator coaching

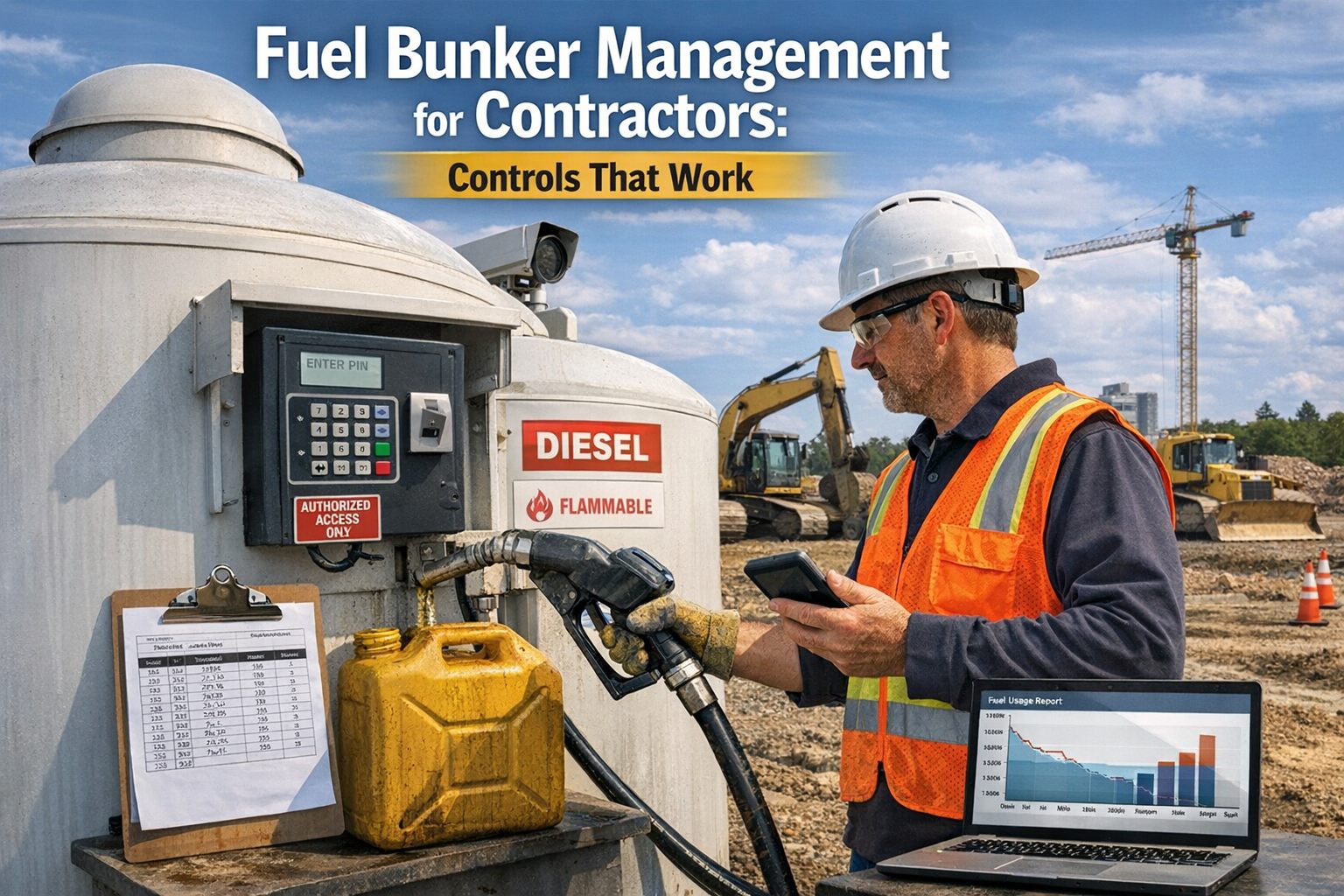

Strategy #4

Job Site & Route Optimization

Poor haul road conditions, excessive grades, inefficient material placement increase fuel 12-18%. Optimize haul routes—maintain roads, minimize grades, reduce travel distance. Plan equipment staging to minimize repositioning. Calculate fuel cost of route decisions.

Savings:

12-18% reduction through route optimization

Strategy #5

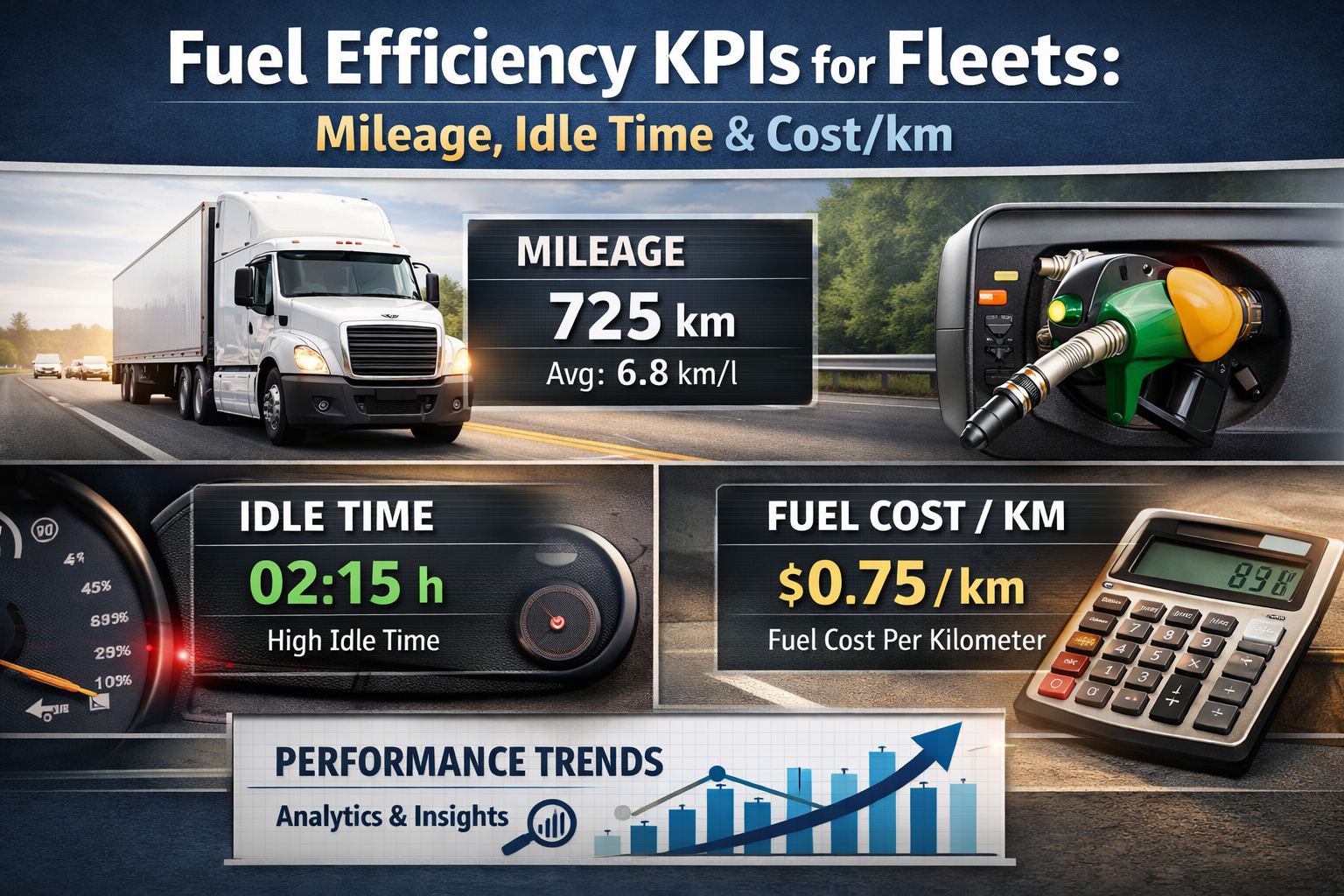

Fuel Monitoring & Analytics

Install telematics tracking fuel consumption, idle hours, operating hours per unit. Compare similar equipment—why does Excavator #7 use 15% more fuel than #8? Identify underperformers, maintenance needs, operator issues. Data drives all other strategies.

Foundation:

Monitoring enables all other fuel reduction strategies

90-Day Fuel Reduction Roadmap

Install fuel monitoring (telematics or manual tracking)

Establish baseline: fuel/hour, idle %, cost per unit

Implement idle reduction policy with daily tracking

→

Complete PM on all units (filters, oil, tires, systems)

Train operators on fuel-efficient operation

Launch weekly operator scorecards

Target: Additional 8-10% reduction from maintenance + training

→

Optimize haul routes and job site layout

Address underperforming units identified by data

Refine targets based on 60-day results

Total: 15-22% cumulative fuel cost reduction

Fuel Reduction Action Checklist

| Strategy |

Implementation Steps |

Expected Savings |

| Idle Reduction |

5-min shutoff policy, daily tracking, operator alerts, auto-shutoff systems |

8-12% total fuel cost reduction |

| Preventive Maintenance |

Hour-based PM schedule, air filters, oil changes, tire pressure, track tension |

8-12% efficiency improvement |

| Operator Training |

Efficient operation training, weekly scorecards, monthly coaching sessions |

10-15% efficiency gain |

| Route Optimization |

Haul road maintenance, grade reduction, distance minimization, staging optimization |

12-18% reduction on haul trucks |

| Fuel Monitoring |

Telematics installation, baseline tracking, performance comparison, analytics |

Enables all other strategies |

Real Heavy Equipment Fleet Results

Baseline: $2.1M annual fuel spend, 47% idle time, no monitoring

Installed telematics on all equipment. Reduced idle from 47% to 18% through policy and operator coaching. Fixed 14 units with maintenance-related efficiency issues. Optimized haul routes saving 8% distance.

90-Day Result: $387K annual savings (18% reduction)

Baseline: High fuel costs, unknown performance per unit

Implemented comprehensive PM program. Trained operators on fuel-efficient techniques. Weekly scorecards published—bottom 20% coached monthly. Tracked fuel/hour per equipment type.

90-Day Result: 16% fuel reduction, $214K annual savings

Baseline: Inefficient haul routes, excessive idle, deferred maintenance

Redesigned haul roads (reduced grades, improved surface). Cut idle from 38% to 12% with auto-shutoff. Completed deferred PM on all units—improved average fuel economy 11%.

90-Day Result: 22% fuel reduction, $127K annual savings

Critical Reality: Heavy equipment typically wastes 20-25% of fuel through preventable causes—excessive idle time (40% of waste), deferred maintenance (30%), poor operator technique (20%), and inefficient routes (10%). These aren't fixed costs; they're controllable variables. The most successful fleets attack idle time first (quickest ROI), then maintenance and operator training. Without monitoring systems, you can't identify which specific units or operators waste fuel. Start with tracking—it enables everything else.

Start Reducing Heavy Equipment Fuel Costs Today

Fleet Rabbit tracks idle time, maintenance schedules, and operator performance automatically for heavy equipment fleets.

Start Tracking

Get Assessment

Frequently Asked Questions

Q

What's the fastest way to reduce fuel costs in heavy equipment?

Idle time reduction delivers fastest ROI. Implement 5-minute auto-shutoff policy, track idle hours daily, alert operators exceeding limits. Most fleets reduce idle 50-60% in 30 days—translates to 8-12% total fuel savings. Equipment burning 1 gallon/hour idling × 1,500 annual idle hours = 1,500 wasted gallons ($5,250). Quick win that pays for monitoring systems within weeks.

Q

How much does poor maintenance hurt fuel efficiency?

Dirty air filters: 10% efficiency loss. Wrong oil viscosity: 3-5% loss. Low tire pressure: 5-8% loss. Worn undercarriage: 8-12% loss on tracked equipment. Cumulative effect: 15-25% efficiency degradation. Preventive maintenance isn't expense—it's fuel cost reduction. PM program typically pays for itself 3-4x through improved efficiency alone.

Q

Can we reduce costs without expensive telematics systems?

Basic tracking: manual hour meter readings, fuel receipts, calculate gallons/hour. Can implement idle policy, PM schedule, operator training without telematics. Limitation: No idle time data, no real-time alerts, can't identify specific waste sources. For 10+ equipment fleet, telematics ($30-$60/unit/month) recovers cost within 60 days through improved management alone.

Q

What's a realistic fuel cost reduction target?

First 90 days: 15-22% reduction is realistic for fleets with no previous controls. Year one: 18-25% cumulative savings typical. Ongoing: 2-3% annual improvement through continuous optimization. Industry leaders maintain 25-30% better fuel efficiency than average fleets. If you're not tracking idle time, doing preventive maintenance, and monitoring performance—you have 20%+ improvement opportunity.