Your fleet spent $127,000 on fuel last month, but you can't explain if that's good or bad. Without tracking specific KPIs, you're driving blind—unable to identify inefficient vehicles, wasteful drivers, or improvement opportunities. Fleets tracking the right fuel efficiency KPIs reduce costs 12-18% within 90 days. The three critical metrics: MPG/fuel economy, idle time percentage, and cost per kilometer. Start tracking fuel efficiency KPIs that actually reduce costs, or schedule a free KPI assessment to see where you're losing money.

67%

Of Fleets Don't Track Basic Fuel KPIs

14%

Average Fuel Savings With KPI Tracking

$8,200

Annual Savings Per Vehicle (KPI-Driven)

60 Days

To Measurable Improvement With KPIs

Why Fuel Efficiency KPIs Matter

- Can't identify problems - Don't know which vehicles or drivers waste fuel

- No improvement targets - Can't set goals without baseline metrics

- React to costs - Only notice issues when bills spike

- No accountability - Drivers have no performance feedback

Result: 15-20% higher fuel costs, no visibility into waste

- Pinpoint inefficiency - Know exactly which vehicles/drivers need attention

- Data-driven targets - Set realistic improvement goals based on baselines

- Proactive optimization - Catch issues before they cost thousands

- Driver accountability - Scorecards drive behavior improvement

Result: 12-18% fuel savings, continuous improvement

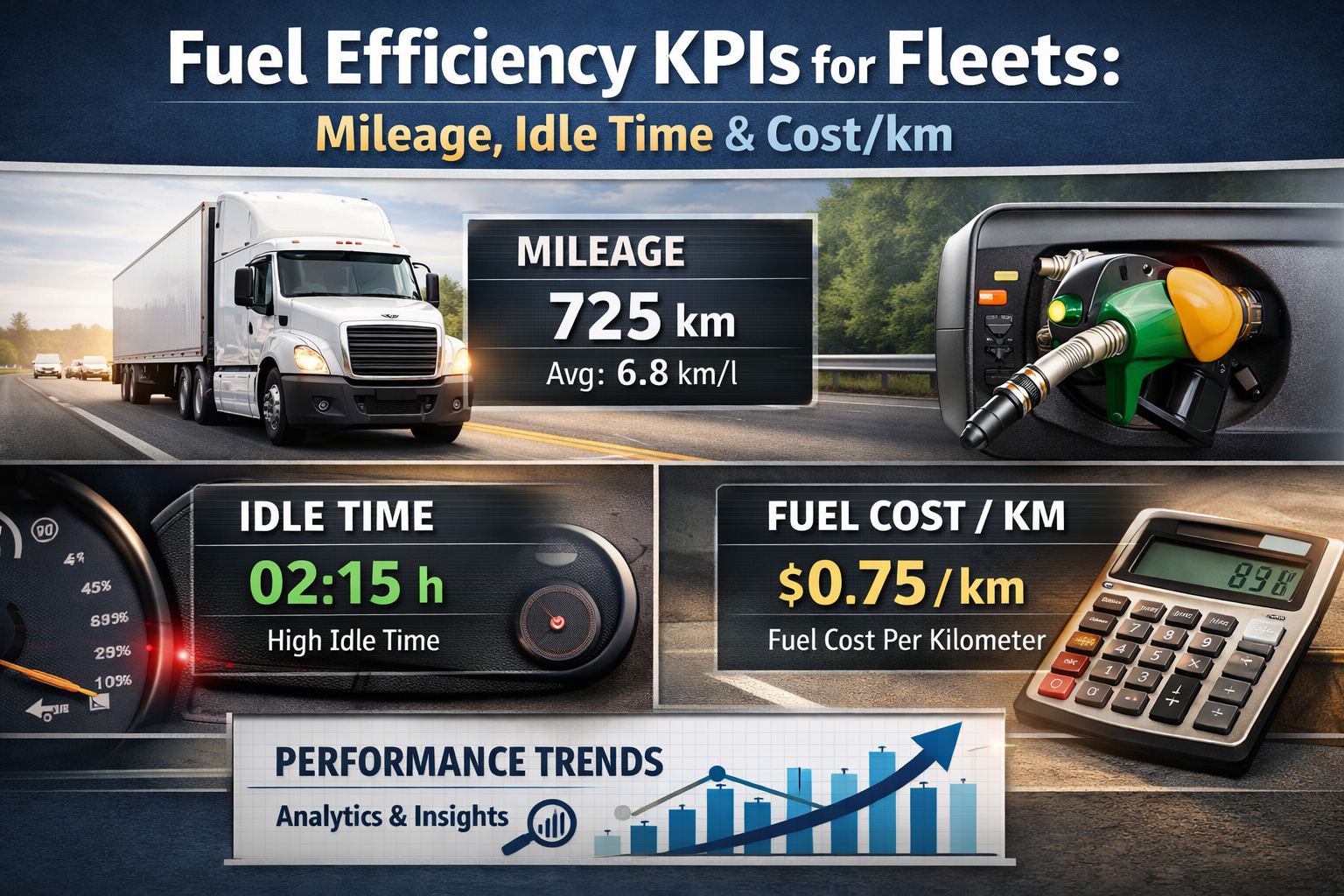

3 Critical Fuel Efficiency KPIs

KPI #1

MPG / Fuel Economy

Miles (or kilometers) per gallon/liter for each vehicle. Compare to baseline and fleet average. Track trends weekly—5% degradation indicates maintenance needs or driver behavior issues. Most important KPI for identifying underperforming vehicles.

Target:

Within 5% of baseline, improving 2-3% annually

KPI #2

Idle Time Percentage

Percentage of engine-on time spent idling (not moving). Heavy vehicles burn 0.8-1.5 gallons/hour idling. Calculate: (Total idle hours ÷ Total engine hours) × 100. Flag vehicles exceeding 10-15% for immediate driver coaching. Want to track idle time automatically? Sign up for Fleet Rabbit's telematics integration with instant idle alerts.

Best Practice:

Under 10% idle time for most operations

KPI #3

Fuel Cost Per Kilometer

Total fuel cost divided by kilometers driven. Normalizes performance across different vehicle types and routes. Track monthly trends—increasing cost/km signals efficiency problems even if fuel prices are stable. Essential for route profitability analysis.

Analysis:

Compare similar vehicles, flag 10%+ variance

KPI #4

Fuel Cost Per Revenue Hour

Fuel cost divided by billable/revenue hours worked. Shows fuel efficiency relative to productivity. More useful than cost/km for equipment that operates stationary (excavators, generators). Identifies equipment needing replacement or repair.

Benchmark:

Track month-over-month, flag 15%+ increases

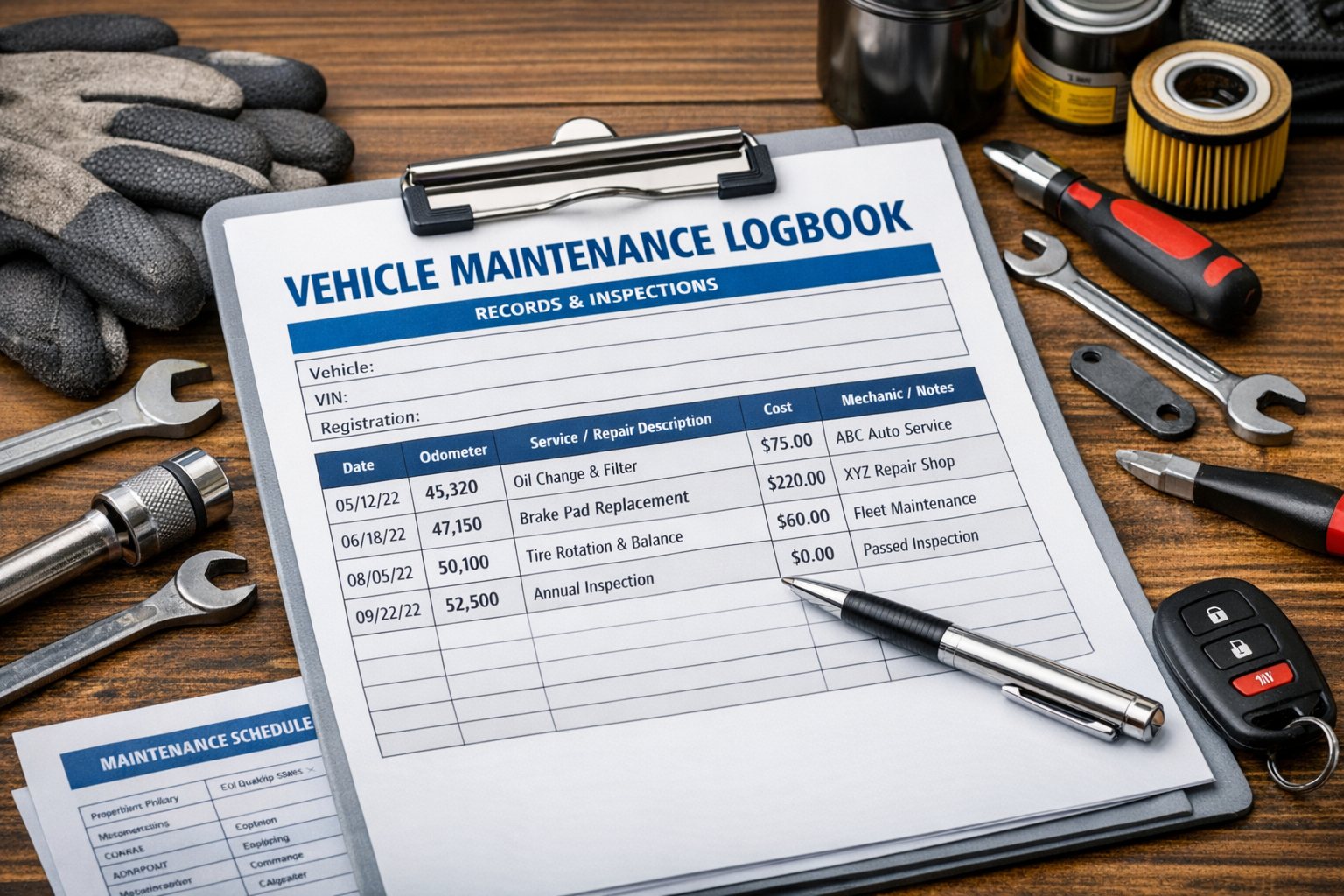

How to Implement KPI Tracking

Calculate current MPG, idle %, cost/km for each vehicle

Identify fleet averages and ranges

Set realistic improvement targets (5-10% in 90 days)

Timeline: Week 1-2 baseline measurement

→

Track idle time daily, alert on violations

Calculate MPG weekly per vehicle

Review cost/km trends weekly

Time: 15-20 min daily, 60 min weekly

→

Rank vehicles by KPI performance

Coach bottom 20% drivers on specific KPIs

Adjust targets based on progress

Review: 2-3 hours monthly strategic analysis. Need help setting up KPI tracking?

Schedule a consultation with our fleet optimization team.

KPI Benchmarks & Targets

| KPI |

How to Calculate |

Target/Benchmark |

| MPG (Fuel Economy) |

Total miles ÷ Total gallons consumed |

Within 5% of baseline, flag 10%+ degradation |

| Idle Time % |

(Idle hours ÷ Total engine hours) × 100 |

Under 10-15% for most operations |

| Cost Per Kilometer |

Total fuel cost ÷ Kilometers driven |

Compare to fleet avg, flag 10%+ variance |

| Cost Per Revenue Hour |

Total fuel cost ÷ Billable hours worked |

Track monthly trends, flag 15%+ increases |

| Fuel Waste % |

(Idle fuel + excess consumption) ÷ Total fuel × 100 |

Under 5% with good controls |

Real Fleet KPI Success Stories

Baseline: No KPI tracking, 6.2 MPG average, 18% idle time

Implemented weekly MPG tracking and daily idle alerts. Identified 12 vehicles with maintenance issues (averaged 5.1 MPG). Coached drivers on idle reduction—from 18% to 8% in 60 days. Cost/km dropped 14%.

90-Day Result: $127K annual savings, 6.9 MPG average

Baseline: Unknown fuel efficiency, high idle hours

Started tracking idle % and cost/revenue hour. Discovered excavators idling 47% of engine time (operators leaving running during breaks). Implemented auto-shutoff policy. Reduced idle from 47% to 12%.

90-Day Result: 1,100 idle hours eliminated, $47K savings

Baseline: Cost/km increasing despite stable fuel prices

Implemented comprehensive KPI dashboard. MPG tracking identified 23 trucks with 8-12% below-average efficiency (tire/alignment issues). Cost/km analysis revealed 15% route inefficiency. Optimized routes and fixed vehicles.

90-Day Result: $340K annual savings, 11% efficiency gain

Critical Success Factor: Most fleets track total fuel spend but not the KPIs that drive improvement. MPG shows vehicle performance, idle time reveals driver behavior, cost/km identifies route inefficiency. Without these metrics, you can't pinpoint problems or measure progress. The act of tracking KPIs itself drives 60-70% of fuel savings—drivers improve when they know they're being measured. Start with these three KPIs and expand from there.

Start Tracking Fuel Efficiency KPIs Today

Fleet Rabbit's automated dashboard calculates MPG, idle %, cost/km, and trends automatically.

Get KPI Dashboard

See Demo

Frequently Asked Questions

Q

What's the single most important fuel efficiency KPI?

MPG (fuel economy) for vehicles that move, idle time percentage for all equipment. MPG shows overall vehicle and driver performance—captures maintenance issues, driving behavior, route efficiency in one number. Idle % has fastest ROI—most fleets reduce idle 40-60% within 30 days just by tracking it and coaching drivers. Start with these two, add cost/km third.

Q

How often should we calculate fuel efficiency KPIs?

Idle time: Daily review (catch violations immediately). MPG: Weekly calculation (smooth out daily variance). Cost/km: Weekly trending. Monthly comprehensive review comparing all KPIs, ranking vehicles, setting new targets. Automated systems calculate continuously—you just review dashboards on this schedule.

Q

Can we track KPIs without telematics systems?

Basic MPG and cost/km: Yes, using fuel receipts and odometer readings in spreadsheet. Limitation: No idle time data, no real-time alerts, time-consuming manual entry. Telematics ($25-$45/vehicle/month) automates everything and adds idle tracking. For 15+ vehicles, telematics ROI appears in 30-60 days from fuel savings alone.

Q

What's a realistic fuel savings target with KPI tracking?

Expect 8-12% savings in first 90 days (quick wins: idle reduction, worst driver coaching). 12-18% savings by 6 months (includes route optimization, vehicle maintenance fixes). Industry average: fleets tracking KPIs spend 14% less on fuel than those flying blind. ROI is immediate—even 5% savings typically exceeds all tracking system costs.