Getting an annual vehicle inspection failure can be frustrating, especially for fleet managers and vehicle owners who depend on reliable transportation. Whether it's your first annual vehicle inspection setback or you're dealing with recurring fleet issues, understanding what went wrong and how to fix it quickly is crucial. At HVI (Heavy Vehicle Inspection), we've helped thousands of clients streamline their vehicle inspection software processes and reduce failures through our comprehensive heavy vehicle inspection software platform.

Understanding Your Annual Vehicle Inspection Report Failure

When your annual vehicle inspection shows a failure, it's not the end of the world. Annual vehicle inspection requirements are designed to ensure road safety, and most failures involve common, fixable issues. At HVI, our vehicle inspection software helps identify potential problems before they become failures, but when issues do arise, understanding what the inspection station found and prioritizing repairs is crucial.

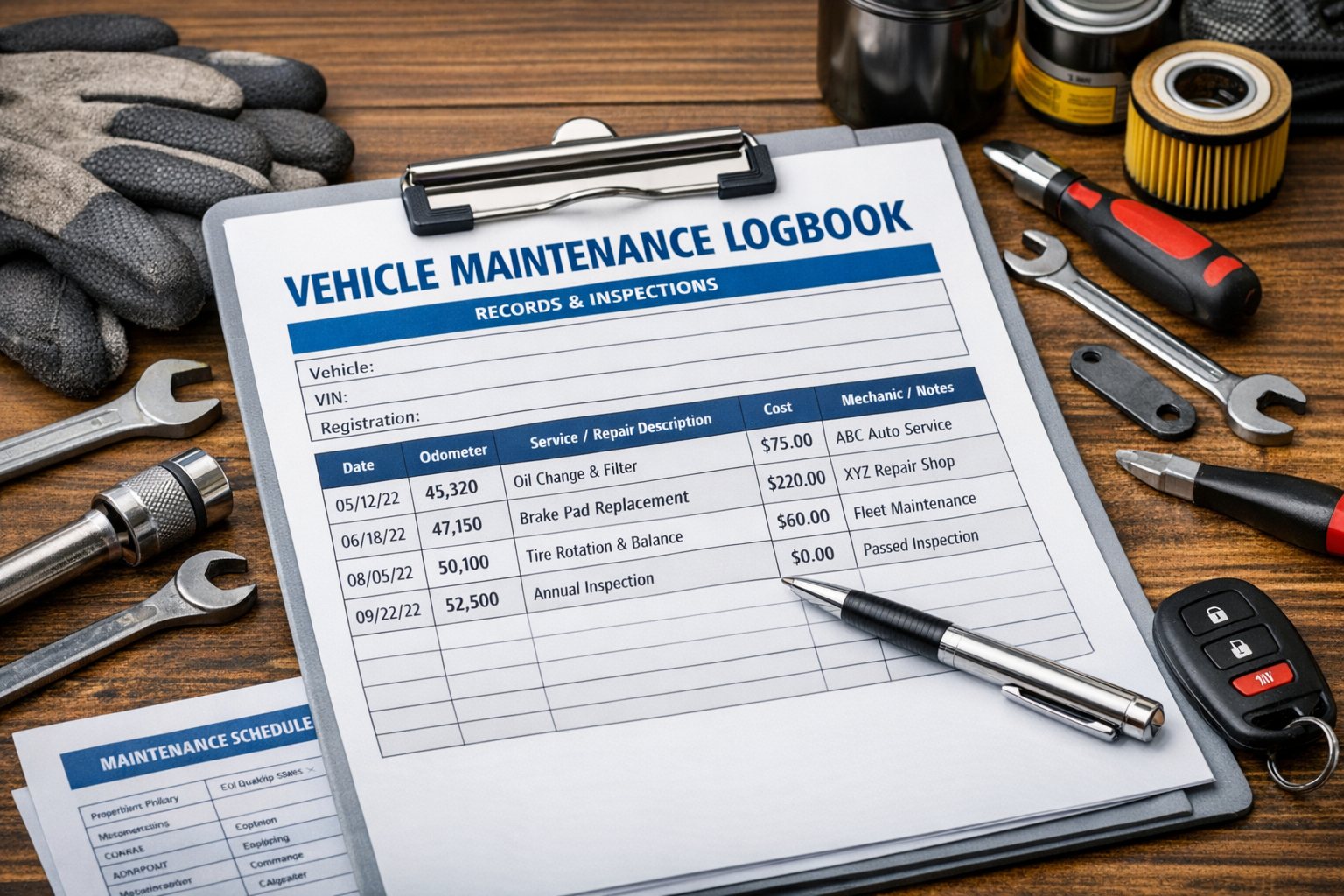

Your inspection certificate will clearly list all failed items, typically categorized by severity. Some states allow minor issues to pass with advisories, while others require all problems to be fixed before issuing a new inspection sticker. Our heavy vehicle inspection software includes state-specific compliance modules to help you understand local annual vehicle inspection requirements and prepare accordingly.

Prevent Inspection Failures with HVI Software!

Our heavy vehicle inspection software helps fleet managers track maintenance schedules, set automated reminders, and ensure compliance before inspection deadlines.

Get Free Demo Start Free TrialAnnual Vehicle Inspection: Most Common Failures and Quick Fixes

Annual Vehicle Inspection: Brake System Issues

Annual vehicle inspection brake failures are among the most serious safety concerns for any fleet. Common issues include worn brake pads, low brake fluid, or damaged brake lines. These problems require immediate attention from qualified mechanics. Our HVI software tracks brake component lifecycles and sends automated alerts when replacement is due, helping prevent surprise failures.

Annual Vehicle Inspection: Lighting and Electrical Problems

Annual vehicle inspection lighting failures are the easiest and cheapest inspection issues to fix. Most headlight alignment problems and bulb replacements can be completed the same day. Don't forget to check turn signals, hazard lights, and license plate illumination. The HVI platform includes pre-inspection checklists that help drivers and fleet managers identify lighting issues before official inspections.

Annual Vehicle Inspection: Emissions and Environmental Failures

Annual vehicle inspection emissions failures often relate to the check engine light, faulty oxygen sensors, or issues with the catalytic converter. These problems require diagnostic scan tools to identify specific trouble codes before repairs can begin. Our heavy vehicle inspection software integrates with diagnostic tools to track error codes and maintenance history, making troubleshooting faster and more efficient.

Annual Vehicle Inspection: Step-by-Step Guide to Fix Failures

Once you receive your failed annual vehicle inspection report, follow these steps to get back on the road quickly. For fleet managers using our HVI software, these steps can be automated and tracked digitally:

Step 1: Prioritize Safety-Critical Issues

Address brake problems, steering issues, and suspension system failures first. These directly impact your safety and the safety of other drivers. Tie rods, ball joints, and wheel bearings fall into this category.

Step 2: Handle Quick Fixes

Replace burned-out bulbs, fix windshield wipers, and address mirror adjustment issues. These are typically DIY repairs that can be completed in under an hour.

Step 3: Schedule Professional Repairs

For complex issues like engine problems, transmission concerns, or extensive exhaust system repairs, schedule an appointment with a reputable auto repair shop. Ask for a detailed repair estimate and timeline.

Ready to Schedule Your Re-Inspection?

Find inspection stations near you and book your appointment online. Most locations offer same-day service!

Schedule Inspection Get a full analysisAnnual Vehicle Inspection: Preventing Future Failures

The best way to avoid annual vehicle inspection failure stress is through regular preventive maintenance and using digital tools like our HVI platform. Create a pre-inspection checklist and address potential issues before your annual inspection date. Our vehicle inspection software automates this process with customizable maintenance schedules and inspection reminders.

Annual Vehicle Inspection: Understanding State-Specific Requirements

Annual vehicle inspection laws vary significantly by state. Some states require only emissions testing, while others mandate comprehensive safety inspections. Understanding your local annual vehicle inspection requirements helps you prepare appropriately. Our HVI software includes state-specific compliance modules that automatically adjust inspection checklists based on your fleet's operating locations.

Most states require annual vehicle inspection renewals, but some have biennial programs. Your vehicle registration renewal often coincides with annual vehicle inspection requirements, so plan accordingly to avoid last-minute rushes. The heavy vehicle inspection software platform tracks all renewal dates and sends automated reminders to fleet managers and drivers.

Transform Your Fleet Management with HVI Software

Join thousands of fleet managers who have reduced inspection failures by 85% using our heavy vehicle inspection software. Streamline compliance, automate maintenance tracking, and eliminate surprise failures.

Free Demo Start Free TrialConclusion: Getting Back on the Road Quickly

An annual vehicle inspection failure doesn't have to derail your fleet operations. By understanding common failure points, prioritizing repairs effectively, and leveraging digital tools like HVI's heavy vehicle inspection software, most vehicles can pass annual vehicle inspection re-testing within 24-48 hours.

Remember that annual vehicle inspection requirements exist for your safety and the safety of others on the road. While it might be inconvenient in the short term, maintaining your vehicles properly ensures reliable fleet operations and helps you avoid more expensive repairs down the road. Our vehicle inspection software makes this process seamless and efficient.

Don't let annual vehicle inspection anxiety keep you from addressing necessary repairs. With the right approach, professional help when needed, and digital management tools like the HVI platform, you'll have your inspection certificates and be back on the road safely in no time. Visit heavyvehicleinspection.com to learn how our software can transform your fleet management and reduce inspection failures.