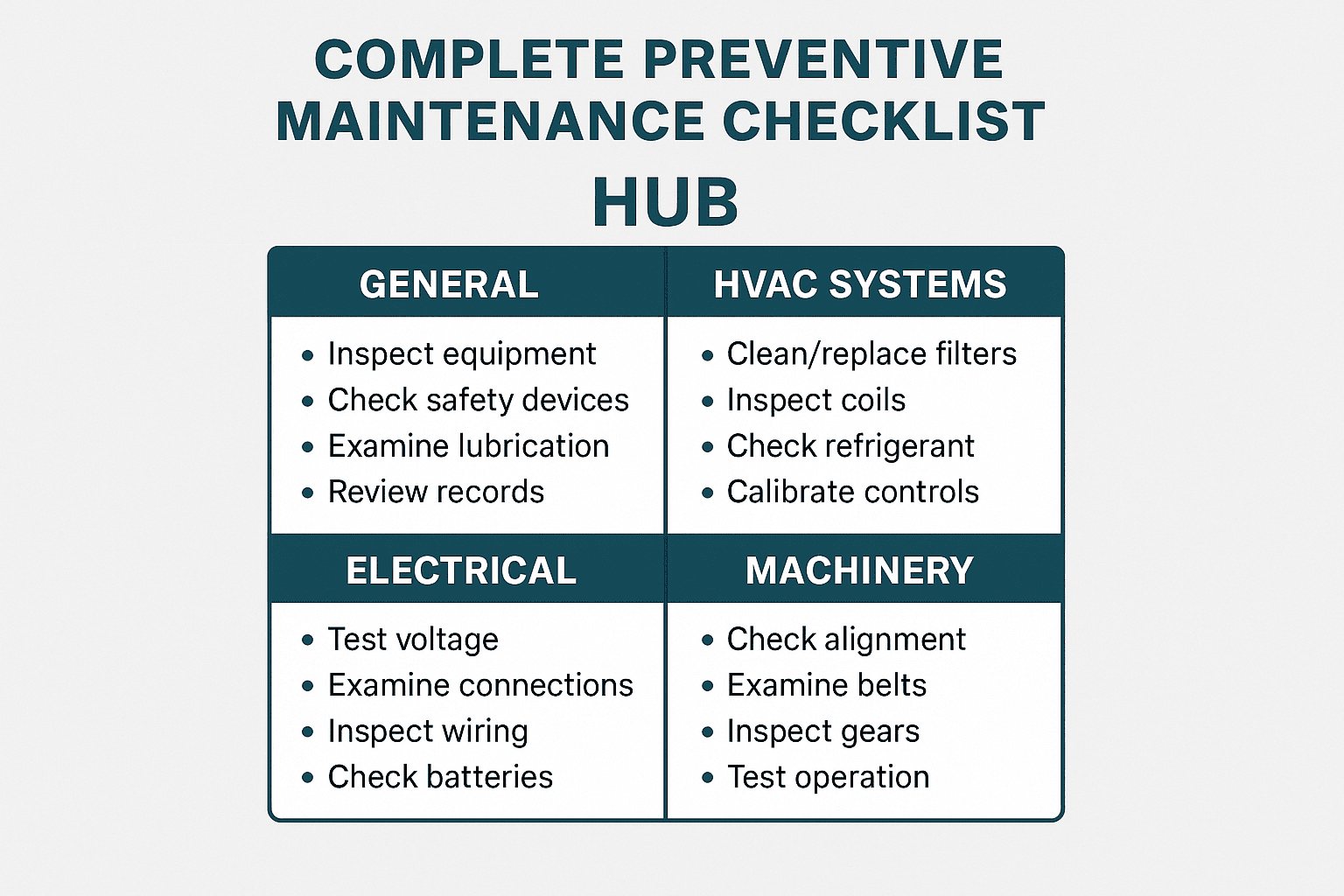

Complete Preventive Maintenance Checklist Hub

Welcome to the most comprehensive preventive maintenance checklist resource available. This hub provides everything maintenance professionals need to implement world-class PM programs across all industries and equipment types. From fleet vehicles to manufacturing equipment, HVAC systems to industrial machinery, our professionally designed checklists help organizations maximize uptime, reduce costs, and ensure regulatory compliance.

Complete Preventive Maintenance Checklist

Download Your HVI Checklist PDF — Start Improving Uptime Today

Our preventive maintenance checklist collection includes time-based, usage-based, and condition-based maintenance schedules that align with OEM recommendations, industry standards and regulatory requirements. Each checklist is developed by maintenance experts, and continuously updated to reflect current best practices in reliability-centered maintenance.

Fleet Preventive Maintenance Schedules

Comprehensive PM checklists for every service interval

PM Schedule A (Every 5,000 Miles)

Essential maintenance tasks for light-duty vehicles at 5K mile intervals.

- Engine oil and filter change

- Tire rotation and pressure check

- Brake inspection

- Fluid level checks

- Battery test

- Multi-point safety inspection

PM Schedule B (Every 12,000 Miles)

Intermediate maintenance for commercial vehicles at 12K mile intervals.

- All Schedule A items

- Transmission service

- Cabin air filter replacement

- Wheel alignment check

- Exhaust system inspection

- Cooling system flush

PM Schedule C (Every 24,000 Miles)

Major service interval for fleet vehicles requiring comprehensive maintenance.

- All Schedule B items

- Spark plug replacement

- Fuel filter change

- Differential service

- Power steering flush

- Suspension component check

PM Schedule D (Annual Service)

Comprehensive annual inspection and maintenance for all fleet vehicles.

- DOT annual inspection

- Complete brake system service

- Full safety inspection

- Emissions testing

- A/C system service

- Complete fluid replacement

5,000 Mile PM - Light Duty Fleets

Specialized maintenance checklist for light-duty commercial vehicles.

- Oil and filter service

- Tire wear assessment

- Light-duty brake inspection

- Windshield wiper check

- Interior safety equipment

- Basic diagnostic scan

10,000 Mile PM - Medium Duty Trucks

Essential maintenance checklist for medium-duty commercial trucks.

- Complete oil and filter service

- Air brake system inspection

- Chassis lubrication

- Tire condition and rotation

- DEF system check

- Fifth wheel inspection

15,000 Mile Maintenance - Commercial Fleets

Mid-range service interval for medium-duty commercial vehicles.

- Engine air filter replacement

- Fuel system cleaning

- Brake fluid test

- Belt and hose inspection

- Steering component check

- Load test battery

30,000 Mile PM - Fleet Vehicles

Major service milestone for all fleet vehicles requiring extensive maintenance.

- Transmission fluid change

- Coolant system service

- Brake component replacement

- Suspension inspection

- Fuel injector service

- Comprehensive diagnostics

100,000 Mile Maintenance - Heavy Duty

Comprehensive overhaul checklist for heavy-duty commercial vehicles.

- Major component inspection

- Engine overhaul assessment

- Complete drivetrain service

- Suspension rebuild evaluation

- Electrical system overhaul

- Frame and chassis inspection

Why Implement Preventive Maintenance Programs?

Increased Equipment Uptime

Reduce unexpected breakdowns by up to 75% through systematic preventive maintenance

Lower Total Cost

Cut maintenance costs by 12-18% compared to reactive maintenance strategies

Extended Asset Life

Increase equipment lifespan by 20-40% through proper maintenance intervals

Enhanced Safety

Prevent equipment-related accidents through regular safety inspections

Improved Performance

Maintain optimal equipment efficiency and productivity levels

Compliance Assurance

Meet regulatory requirements with documented maintenance records

Types of Preventive Maintenance Programs

Time-Based Maintenance

- Calendar-based scheduling

- Fixed interval maintenance

- Seasonal PM activities

- Annual inspections

- Regulatory compliance dates

- Warranty requirements

Usage-Based Maintenance

- Mileage/hour intervals

- Cycle count triggers

- Production volume based

- Operating hour tracking

- Load-based scheduling

- Performance metrics

Condition-Based Maintenance

- Vibration analysis

- Oil analysis programs

- Thermographic inspections

- Ultrasonic testing

- Performance monitoring

- Real-time sensor data

Predictive Maintenance

- AI-driven predictions

- Machine learning models

- Failure pattern analysis

- IoT sensor integration

- Trend monitoring

- Automated alerts

Transform Your Maintenance Operations Today

Join thousands of organizations using our digital PM platform to reduce costs, improve reliability, and ensure compliance. Get instant access to all preventive maintenance checklists and advanced CMMS features.

PM Program Implementation Best Practices

Asset Prioritization

Focus PM efforts on critical equipment first. Use criticality analysis to identify assets that most impact production, safety, or compliance.

Team Training

Ensure maintenance staff understand PM procedures and importance. Regular training improves compliance and maintenance quality.

Continuous Improvement

Regularly review and optimize PM intervals based on equipment history, failure data, and manufacturer recommendations.

Digital CMMS vs. Traditional PM Methods

While paper-based PM checklists served their purpose, modern CMMS platforms like HVI revolutionize maintenance management with automation, analytics, and real-time visibility that dramatically improve maintenance outcomes.

Digital CMMS Benefits:

- Automated PM scheduling

- Mobile work order management

- Inventory integration

- KPI dashboards

- Predictive analytics

- Multi-site coordination

Manual System Limitations:

- Missed PM schedules

- Paper-based inefficiencies

- No real-time visibility

- Manual reporting burden

- Limited data analysis

- Compliance tracking gaps

Preventive Maintenance FAQs

Preventive maintenance (PM) is a proactive maintenance strategy that involves regularly scheduled inspections, services, and repairs to prevent equipment failures before they occur. It's important because it reduces unexpected downtime by up to 75%, extends equipment life by 20-40%, lowers overall maintenance costs by 12-18%, and improves workplace safety. PM also helps maintain warranty compliance and ensures regulatory requirements are met.

PM intervals should be based on manufacturer recommendations, equipment criticality, operating conditions, and historical failure data. Start with OErocedure Filelines, then adjust based on your specific usage patterns and environment. Consider factors like duty cycle, environmental conditions, age of equipment, and regulatory requirements. Many organizations use a combination of time-based (calendar), usage-based (hours/miles), and condition-based triggers to optimize their PM schedules.

Preventive maintenance follows fixed schedules regardless of equipment condition, while predictive maintenance uses real-time condition monitoring to determine when maintenance is needed. PM is calendar or usage-based (e.g., oil changes every 3,000 miles), while PdM uses technologies like vibration analysis, thermal imaging, or oil analysis to predict failures. Both strategies complement each other in a comprehensive maintenance program, with PdM helping to optimize PM intervals.

Key performance indicators (KPIs) for PM effectiveness include: PM compliance rate (% of PMs completed on time), Mean Time Between Failures (MTBF), equipment availability/uptime percentage, maintenance cost per unit of production, ratio of planned vs. unplanned maintenance work, and overtime hours. Track these metrics monthly and look for trends. A successful PM program typically shows 90%+ PM compliance, increasing MTBF, and a shift from 80% reactive to 80% planned maintenance.

Common challenges include resistance to change from reactive maintenance culture, initial resource investment requirements, determining optimal PM intervals, maintaining PM schedule compliance during busy periods, and tracking/analyzing maintenance data effectively. Solutions include starting with critical equipment first, using CMMS software for automation, providing training on PM benefits, establishing clear accountability, and celebrating early wins to build momentum. Digital platforms like HVI help overcome many of these challenges through automation and visibility.

Start Your Preventive Maintenance Journey

This Complete Preventive Maintenance Checklist Hub provides the foundation for world-class maintenance programs across all industries. Whether you're maintaining a fleet of vehicles, managing facility operations, or overseeing industrial equipment, these comprehensive checklists ensure nothing falls through the cracks while maximizing asset reliability and minimizing costs.

Take your preventive maintenance program to the next level with the HVI platform. Our digital CMMS solution transforms paper-based PM programs into efficient, data-driven operations. With automated scheduling, mobile work orders, real-time dashboards, and predictive analytics, HVI helps maintenance teams achieve excellence while reducing administrative burden.

Join thousands of organizations that have revolutionized their maintenance operations with HVI. From small businesses to Fortune 500 companies, our platform scales to meet your needs while delivering immediate ROI through reduced downtime, lower maintenance costs, and improved asset performance. Start your free trial today and experience the future of preventive maintenance management.

Get 2 Months Free On Annual Plans – Unlock Your Savings Today!

Book A DemoJoin 1000+ fleet managers who have improved their inspection and maintenance process.

Signup NowGET MOBILE APP ON YOUR DEVICE TODAY