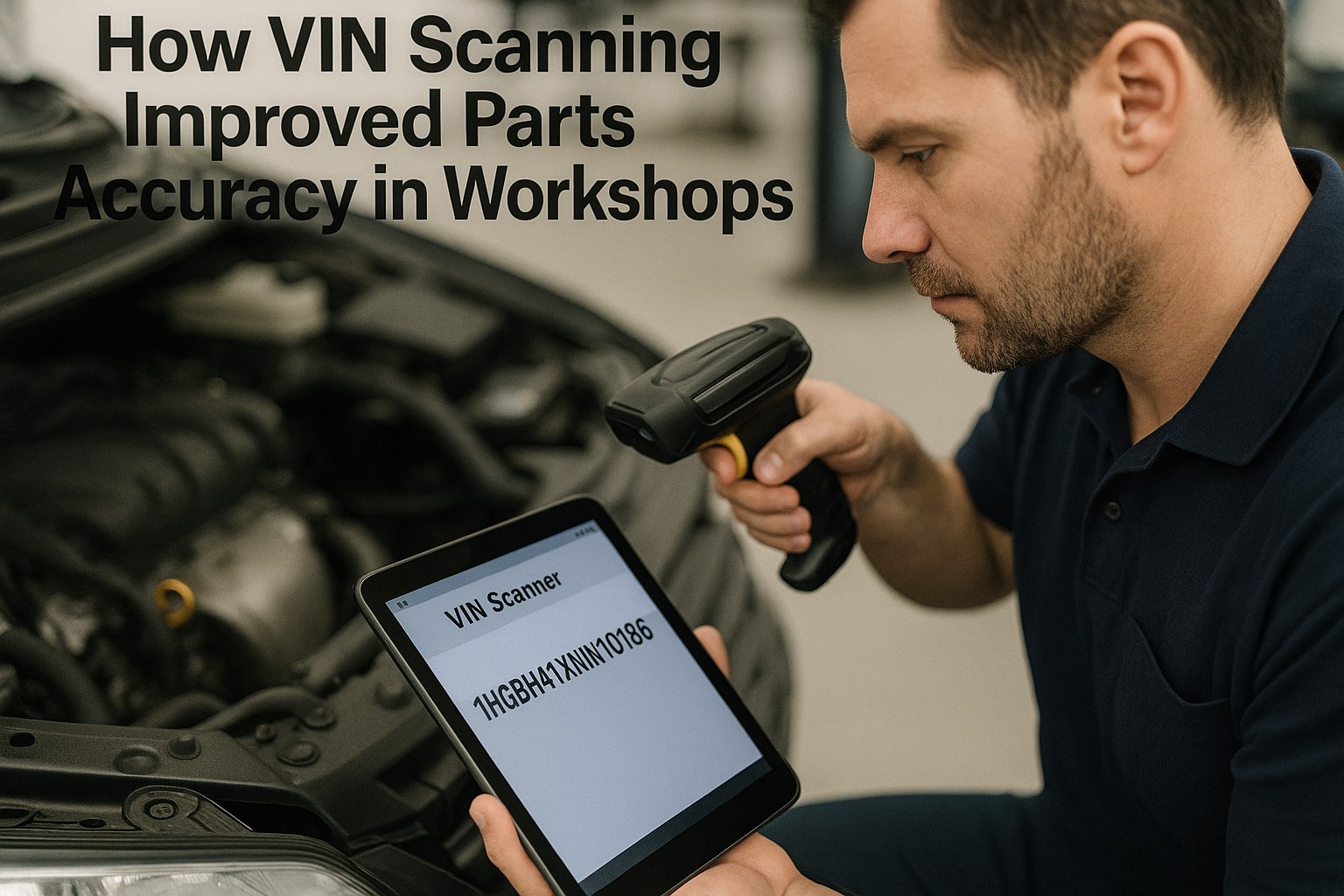

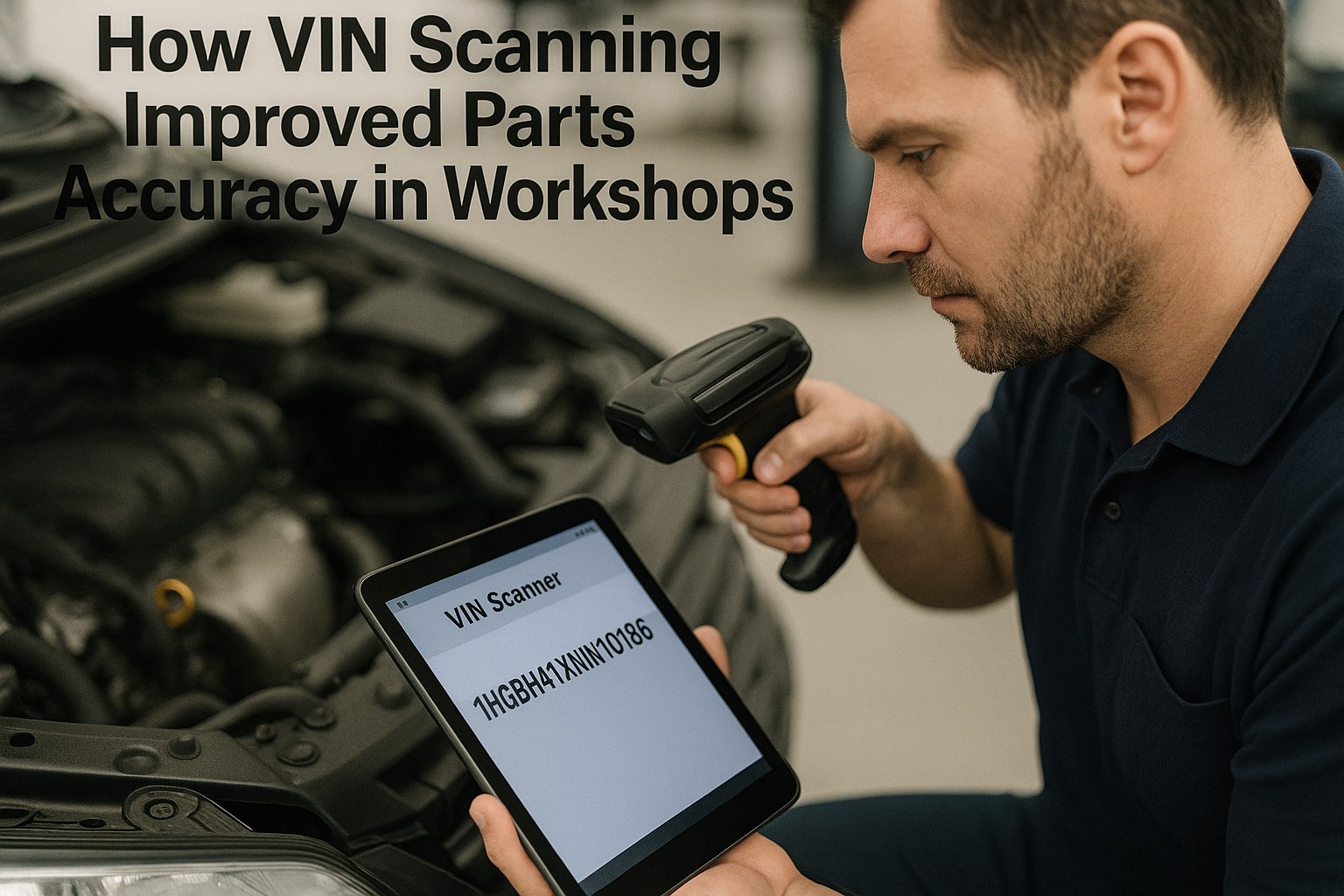

Discover how a California-based fleet maintenance operation revolutionized their parts management through VIN scanning technology, achieving 96% parts ordering accuracy, 84% reduction in ordering errors, and $1.4 million annual savings while managing maintenance for 380 commercial vehicles across seven workshop facilities.

Client Overview

A major California fleet maintenance provider operating seven workshop facilities across Los Angeles, San Francisco, San Diego, and Sacramento, servicing a mixed fleet of 380 commercial vehicles including delivery trucks, service vans, utility vehicles, and specialty equipment. This maintenance operation handles over 12,000 repair orders annually with a team of 85 certified technicians and 15 parts specialists. Operating under strict California emissions regulations and managing diverse vehicle makes and models from 2015-2025, this workshop network faced significant challenges in maintaining parts accuracy while meeting demanding 24-hour turnaround requirements for critical fleet repairs.

The Challenge

This workshop operation was struggling with chronic parts ordering errors that created cascading delays throughout their maintenance operations. Manual VIN lookups and parts cross-referencing consumed hours of technician time daily, while incorrect parts orders resulted in expensive returns, extended vehicle downtime, and frustrated customers. Without automated VIN scanning capabilities, parts accuracy averaged only 71%, creating operational bottlenecks and destroying profitability.

- 29% parts ordering error rate causing repair delays and rework

- $1.8 million annual losses from wrong parts and return shipping

- 45 minutes average per manual VIN lookup and parts identification

- 18% of repairs delayed due to incorrect parts ordering

- No standardized parts identification across workshop locations

- Manual data entry errors affecting 1 in 4 repair orders

- Technician productivity lost to parts research and verification

- Inventory carrying costs inflated by duplicate wrong parts

- Customer satisfaction scores declining due to repair delays

- Warranty claim rejections from incorrect parts documentation

If your workshop is experiencing similar parts ordering challenges, accuracy issues, or technician productivity losses, discover our VIN scanning solutions to eliminate errors and accelerate repairs.

The Solution

This workshop network partnered with HeavyVehicleInspection.com to implement an advanced VIN scanning system that transformed their parts ordering accuracy and workshop efficiency. The HVI solution provided instant vehicle identification, automated parts lookup, and integrated ordering systems that eliminated manual errors and accelerated repair processes across all facilities.

Instant identification

Accurate selection

Error-free processing

HVI VIN Scanning Platform Features:

- Mobile VIN scanning with OCR technology for instant capture

- Comprehensive vehicle database covering 25+ years of models

- Real-time parts catalog integration with OEM specifications

- Automated cross-reference checking for aftermarket alternatives

- Multi-supplier price comparison and availability checking

- Digital parts ordering with automated PO generation

- Service history integration for predictive parts requirements

- Warranty verification and compliance documentation

- Inventory management with automatic reorder triggers

- Workshop floor tablets for technician-direct scanning

The HVI VIN scanning system seamlessly integrated with the workshop's existing management software, parts supplier systems, and inventory databases, creating a unified parts ecosystem that ensured accuracy from vehicle identification through parts installation. Advanced algorithms validated every parts selection against vehicle specifications, preventing ordering errors before they occurred. Want to see how this technology can transform your workshop operations? Schedule a personalized demo to experience VIN scanning in action.

Workshop Performance Improvements

| Performance Metric | Before HVI | After HVI | Improvement |

|---|---|---|---|

| Parts Accuracy | 71% correct orders | 96% correct orders | +35.2% |

| Order Errors | 29% error rate | 4% error rate | -86.2% |

| Lookup Time | 45 minutes average | 90 seconds average | -96.7% |

| First-Time Fix | 82% success rate | 97.3% success rate | +18.7% |

These remarkable improvements demonstrate how VIN scanning technology eliminates inefficiency and drives profitability. Ready to calculate your workshop's potential savings? Get started today and unlock your workshop's full potential.

The Results

Within ten months of implementing HVI's VIN scanning system, this workshop network achieved remarkable transformation in parts accuracy, operational efficiency, and customer satisfaction across all seven facilities.

Parts Accuracy Rate

Error Reduction

Time Saved Per Order

First-Time Fix Rate

Technician Productivity

28% efficiency increase

32 more repairs daily

Return Shipping Savings

$385,000 reduction

91% fewer returns

Customer Satisfaction

4.8/5.0 rating

From 3.9/5.0 previously

Achieving 96% parts accuracy and $1.4 million in annual savings isn't just possible—it's happening right now for forward-thinking workshops. Book a consultation to learn how your workshop can achieve similar results.

- VIN scanning reducing vehicle identification time by 96.7%

- Automated parts matching eliminating 84% of ordering errors

- Digital catalog integration providing instant access to 2M+ parts

- Multi-supplier connectivity ensuring best price and availability

- Technician productivity improved by 28% through time savings

- Inventory optimization reducing carrying costs by $425,000

- Warranty compliance achieved through accurate documentation

- Same-day parts availability increased from 67% to 94%

- Administrative burden reduced by 70% through automation

- Workshop capacity increased by 23% without adding staff

"Implementing HVI's VIN scanning system was a game-changer for our workshop operations. We went from constant parts ordering chaos to streamlined efficiency almost overnight. The 96% accuracy rate has virtually eliminated comeback repairs due to wrong parts, while saving our technicians over 40 minutes per repair order. The $1.4 million in annual savings is impressive, but the real victory is our technicians' improved morale and our customers' trust in getting repairs done right the first time. This technology has transformed how we operate."

— Director of Workshop Operations, California Fleet Maintenance NetworkYour workshop can achieve this same level of transformation. Whether you operate a single facility or multiple locations, our VIN scanning platform scales to meet your needs. Start your parts accuracy journey and join industry leaders in workshop excellence.

Transform Your Workshop Parts Management

Stop losing money and time to parts ordering errors. Join leading workshop operations across America that have achieved parts excellence with HeavyVehicleInspection.com's VIN scanning technology. With proven results showing 96% accuracy and $1.4 million in annual savings, the question isn't whether VIN scanning works—it's how quickly you can implement it.

Achieve Parts Ordering Excellence Today

Discover how VIN scanning technology can eliminate ordering errors, accelerate repairs, and maximize workshop profitability.

Get Started Now Book Your DemoDon't let another day go by with parts errors costing your workshop money and credibility. Take the first step toward operational excellence and customer satisfaction. Connect with our team to discuss your specific workshop challenges and discover customized VIN scanning solutions that deliver measurable results.

.png)

.png)